IPM International Perforation Management

hi-tech engineering, Germany, Thailand, China

tel/fax: 0049-3212-5375175

http://www.microperforation.com

http://www.deguodaguan.com/ipm/

Email: grosse microperforation.com - perforationpeople web.de

copyright Werner Grosse Patent download http://www.microperforation.com/englishengineerreport.html main link http://www.microperforation.com/ipm-technology.html IPM PORTFOLIO ENGLISH IPM PORTFOLIO SPANISH anti counterfeiting laser solution MLL-1

Outstanding Micro Cluster Production Technologies

MLL-1 anti piracy micro laser treatment, line perforation real alternative for galvanometer or scanner, super-high speed rotate cone mirror, cluster micro technology for holes pattern, perforation design, waves, zigzag or packages lines, cryptograms, company logos, holograms, anti piracy, counterfeiting, security paper, safety, bank note, metal sticker, printing, laminating, coating, fruit, food, bread, vegetable, agriculture covering, credit cards, transparent film, holographic paper, cigarette, tipping, filter, aluminum foil, shrinkable film, tear tape, cardboard, matrix code, identification, marking, scribing, jewelry, automotive, pharmacy, golf, marina, tobacco, smoking, chemical, medical, product, electronics part, indicator, porosity contours or profile, embossing, bioengineering, membrane, filtration, focus, holographic, hinge-lid, pack. Patent pending DE102004012081.

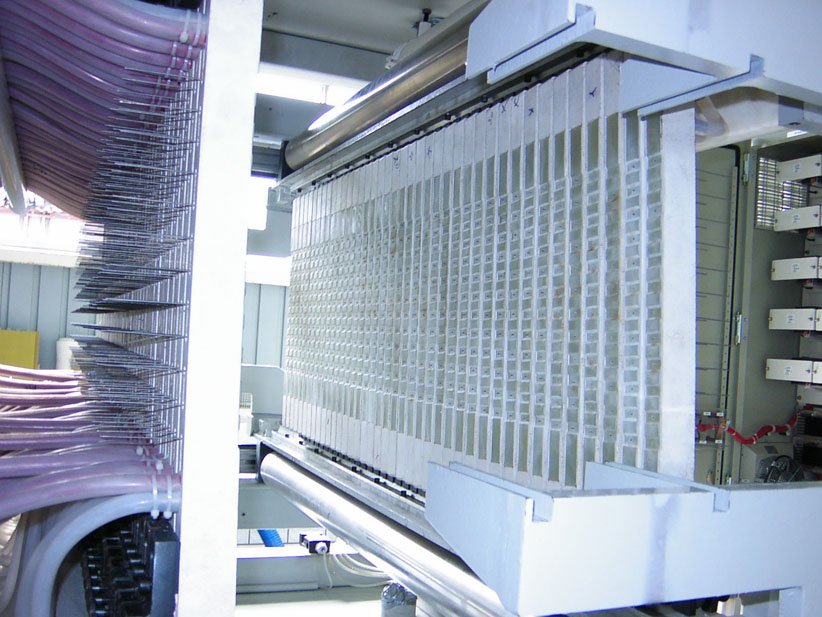

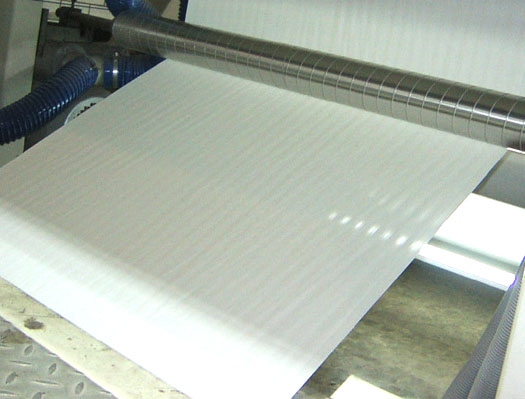

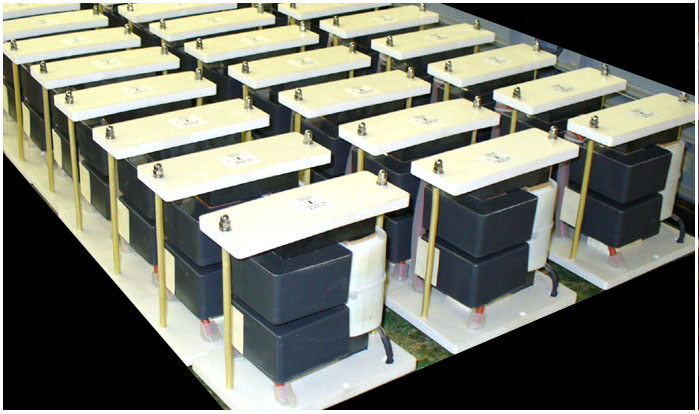

LPM-1 micro laser cluster perforator, material treatment at wide web, large area, surface or entire material cluster treatment, cutting, welding, drilling, ablation, cleaning, melding, high power, ultra high speed rotate quad or twin laser beam splitter, twin level vacuum multiplexer, up to 4 Kilowatt laser input, flexible hollow fibers, HGW, HCW, up to 200 output channels, Co2. Material treatment and robotic handling for stainless steel, ceramic, aluminum, wafer, gold, glass, silver, brass, copper, wafer, silicon, titanium, silicon, solar, panel, photovoltaic, micromachining, slitting, rewinding, refining machines or stand along systems. Micro cluster perforation for all kind of paper or specific plastic web material. Patent granted DE102004001327.

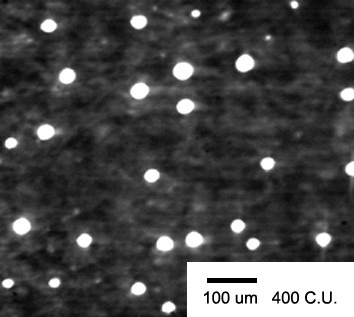

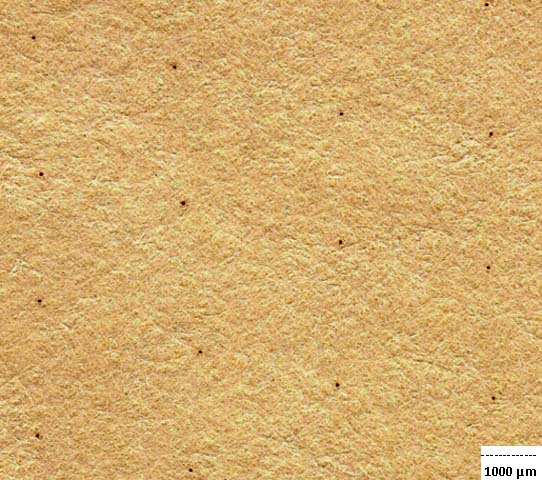

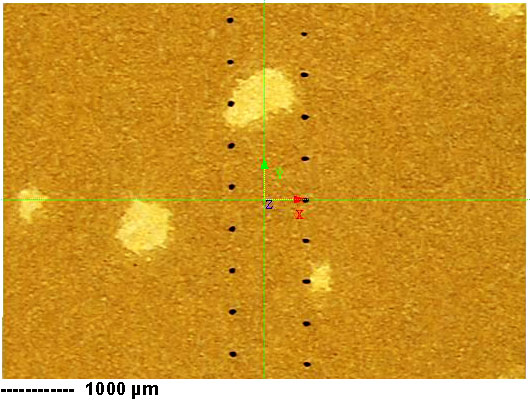

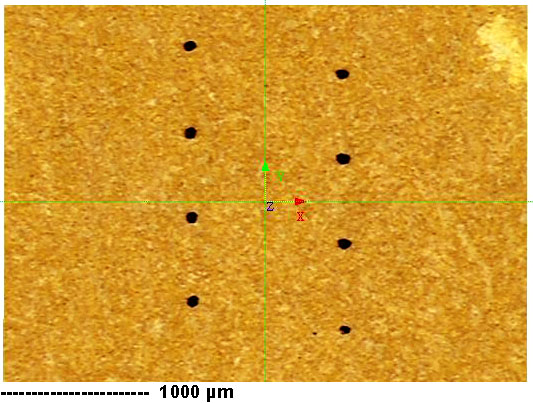

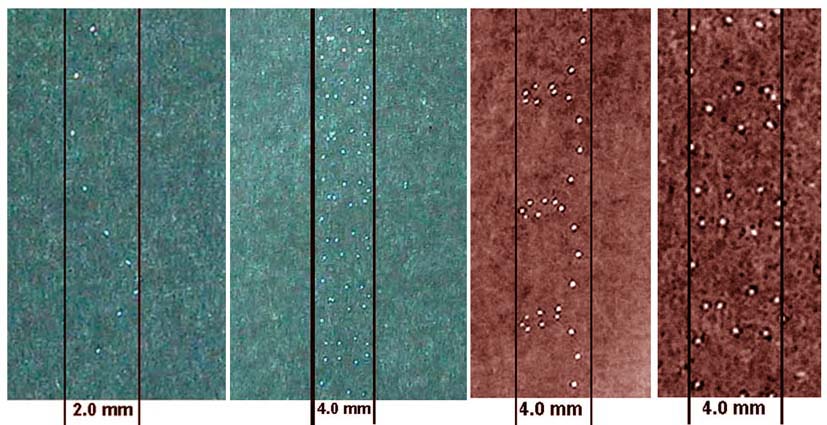

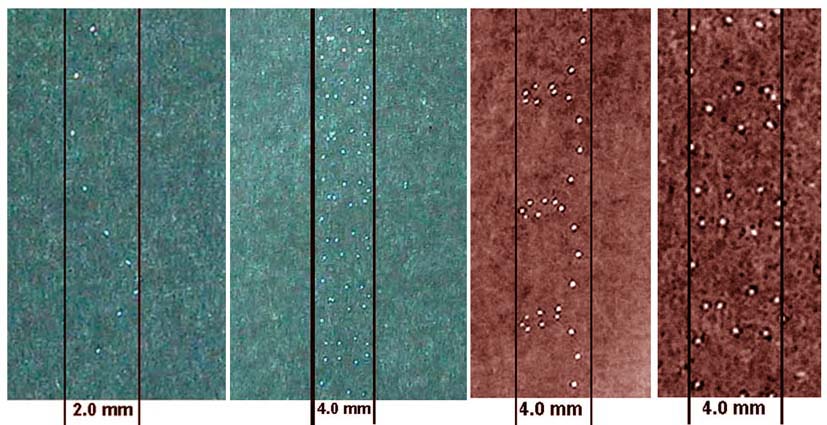

Nano Micro perforation or other material surface treatment, electrostatic cluster perforation, micro perforator, for cigarette, tipping, filter, packaging, plug wrap, Kraft, cement, pet, powder, sack, bag, fine and other paper, silicon or other coating, certain plastic film, laminate, porosity from 80 up to 2,500 C.U., from 50 down to 4 Gurley, hole sizes from 50 nm up to 100 micron, hole densities from 80-260 h/cm2, zone widths from 2.0-6.0mm, up to 16,000,000 holes per Second, web speeds up to 600 m/min, web widths up to 2,000mm. Patent grantededed DE10328937.

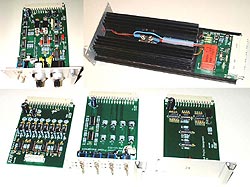

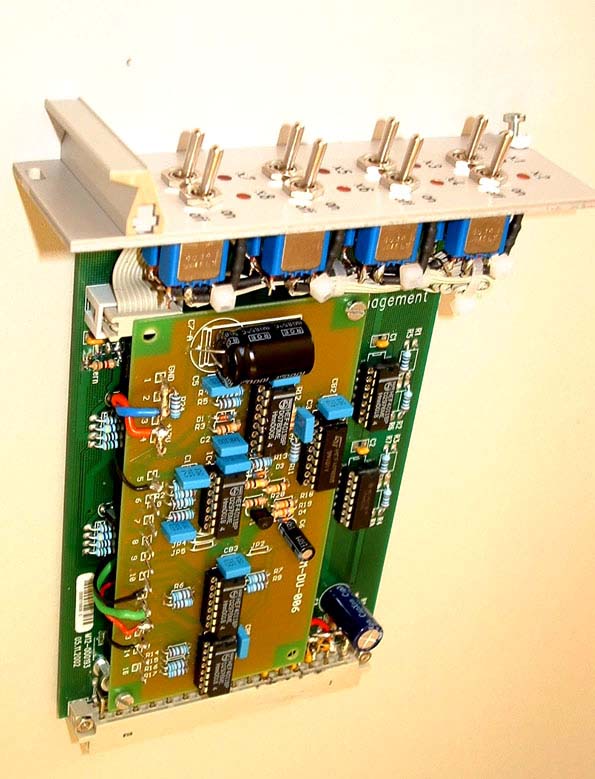

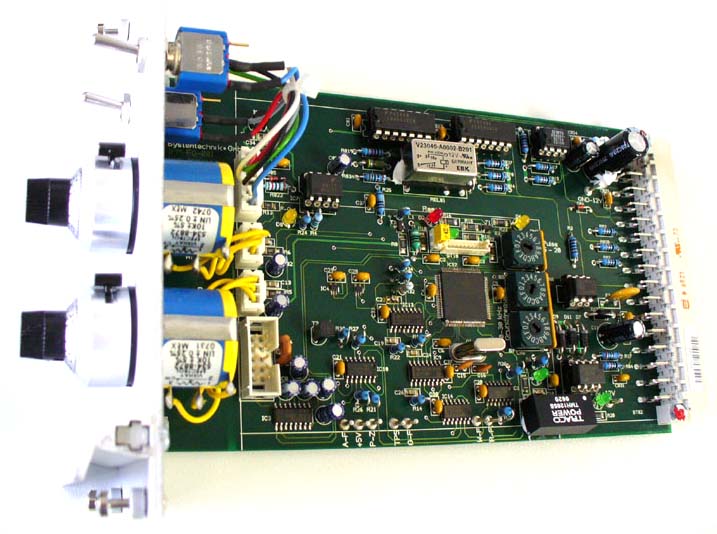

Twin AC/AC, AC/DC frequency shift converter high power, high frequency, high voltage, ultra short mega peak current, electrostatic nano or micro cluster perforation, ignition, sparking, arc, cigarette, tipping, filter, fine, packaging, paper, plug-wrap, sack, bag, Kraft, food, plastic film, foil, textile, fabrics or other product, switching converter, compressor, emergency, train, ship or vessel power supply, generator, fuel cell, upward, downward, frequency shift switching unit, stabilizer, soft starter, vector, phase, inverter, servo system, motion, stepping, machine, asynchronous, standard, motor, torque, automation, remote, gas, slab, laser, diode, stack, fiber, fibre optics, beam, material, hybrid, plug-in, battery, renewable, energy, medical equipment, membrane, filtration, robotic, photovoltaic, industrial automation, drives, IGBT, MOSFET, FRETFET, HVFET, tube, rf, hv. Patent grantededed DE10328937.

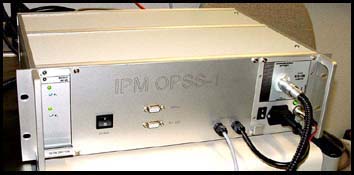

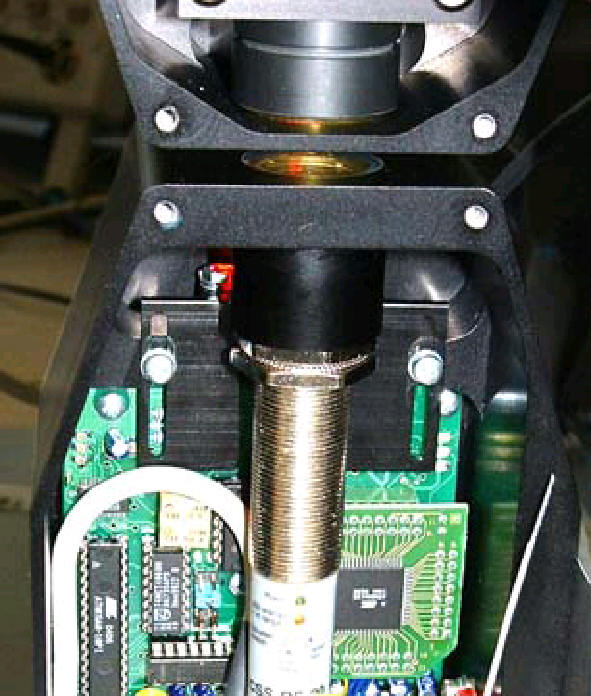

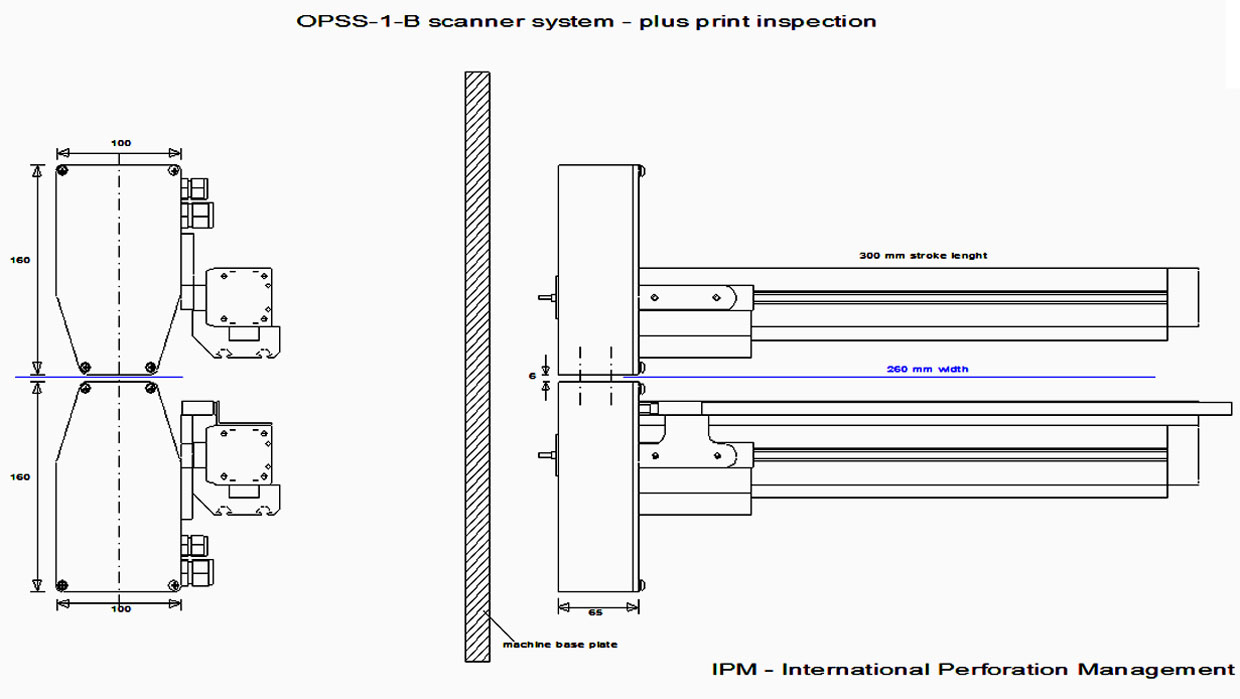

Online OPSS-1 porosity vision scanning control system permeability cluster control for electrostatic or laser micro perforation machines, multiple color sensor head, spectral intensity, DSP, FPGA, CCD, line, precise, laser, position, material finger print detection, VIS wave length, opacity, defects, inspection, image control, scanner systems, process software, line, camera, vision control, filter, tipping, cigarette, book, packaging, magazine, bible, wall, Kraft, paper, coffee, tea, food, co-extrusion foil, film, agriculture, cement, domestic or other moving fabrics or web material. Patent pending DE10251610, China patent granted 200310104764.

in-situ dyne or surface tension control ODSTM-1 at fast moving substrate, plastic, film, foil, tear tape, laminate, co-extrusion, BOPP, LLDPE, LDPE, PE, PP, PVC, MOV, MOH, FEP, PET, OPP, PTFE, MPET, spectral, extinction, monolithic, sensor, analyzing, Subangstrom, roughness, measurement, wavelength, wobbling, stray, light, beaming, water drop, angle, inspection, corona, plasma jet, laser, IR, NIR, scanning, monolithic spectrometer, photonics, spectral, properties, reflectometer, scatterometry, ellipsometry, opto, acoustic, basic, weight, techniques, corona, flam, gas treatment. Previous patent application DE19543289.

Patent references

http://www.wikipatents.com/gb/2149092.html

http://www.wikipatents.com/de/3332886.html

http://www.wikipatents.com/de/2918283.html

http://www.freepatentsonline.com/EP0460369.html

http://www.freepatentsonline.com/7224447.html

http://v3.espacenet.com/publicationDetails/biblio?CC=EP&NR=0460369&KC=&FT=E

http://www.inpama.com/index.php?content=invention&id=18

http://www.inpama.com/index.php?content=invention&id=19

http://www.inpama.com/index.php?content=invention&id=20

http://www.inpama.com/index.php?content=invention&id=21

http://www.inpama.com/index.php?content=invention&id=22

http://www.inpama.com/index.php?content=invention&id=23

http://www.inpama.com/index.php?content=invention&id=24

https://www.patent-net.de/index.php?content=projekt&id=163

https://www.patent-net.de/index.php?content=projekt&id=213

https://www.patent-net.de/index.php?content=projekt&id=155

https://www.patent-net.de/index.php?content=projekt&id=156

https://www.patent-net.de/index.php?content=projekt&id=214

https://www.patent-net.de/index.php?content=projekt&id=157

https://www.patent-net.de/index.php?content=projekt&id=158

https://www.patent-net.de/index.php?content=projekt&id=287

PowerSourcing Links

http://www.PowerSourcing.com/se/lasermicroholedrilling.htm http://www.PowerSourcing.com/se/laserscanning.htm http://www.PowerSourcing.com/se/laseroptics.htm http://www.PowerSourcing.com/sf/electricalpackaginglinedesign.htm http://www.PowerSourcing.com/sf/packaginglinedesignelectrical.htm http://www.PowerSourcing.com/se/paperproducts.htm http://www.PowerSourcing.com/se/coatedtreatedpaper.htm http://www.PowerSourcing.com/sf/microperforation.htm http://www.PowerSourcing.com/sf/lasermicromachining.htm http://www.PowerSourcing.com/se/machinetoolsinspectionqualitycontrol.htm

Micro perforation - archipelagos of technical possibilities

Mikro Perforation – Archipel technischer Möglichkeiten

online porosity, in-situ dyne surface tension control and material inspection systems

Nano Mikro Cluster Technologien für Materialbahn Veredelungen

Zur Atmungsaktivierung, Wasserdampfdurchlässigkeit, Gasaustausch oder Ventilation und unter anderem zur Beibehaltung der Wasserdichtigkeit werden Produkte wie Verbundstoffe, Zigaretten-, Filter-, beschichtete Spezial-, Kraft-, Sack- oder Verpackungspapierbahnen, Vliesstoffe oder technische Textilien mit Flächengewichten von 20 g/m2 bis zu 140 g/m2 elektrostatisch Nano oder Mikro sowie mit feinen Laserstrahlen Mikro oder Makro perforiert. Unter elektrostatischer Nano oder Mikroperforation sind statistisch unregelmäßig verteilte, in der Größe, wenn gewünscht, mit bis zu 40 % variierende und analog hierzu unter Laser Mikro oder Makro Perforation, gleichmäßig angeordnete und im Durchmesser etwa gleichgroße, nach Möglichkeit runde, gradfreie Löcher und Lochreihen verschiedenster Anordnung zu verstehen.

Bei der elektrostatischen Perforation finden im bis 1.5 mm weiten atmosphärischen Elektrodenspalt der meist dünnen oder spitzen, gegenständigen Elektrodenstifte Blümlein- und dielektrisch geförderte Mikroendladungen mit Filamentierung zur Erzeugung eines Plasmentunnels und sich damit aufbauenden, ionisierten Funkenstreckenkanal im Nanosekundenzeitfenster statt. Mit jeder hochspannungstechnischer Entladung und Deionisation im Spannungsbereich bis zu 50.000 Vss, deren Leistungselektronik patentiert ist, entsteht für die im Elektrodenspalt relativ schnell durch bewegte Materialbahn eine elektrostatische Nano oder Mikroperforation mit präzise gesteuerten Energieanteilen von 0.1 bis 3 mJ pro erzeugter Pore, die mit bloßen menschlichen Auge unsichtbar sind und vollflächig wie auch zonenförmig in bestimmten Abständen über die Bahnbreite verteilt sein kann.

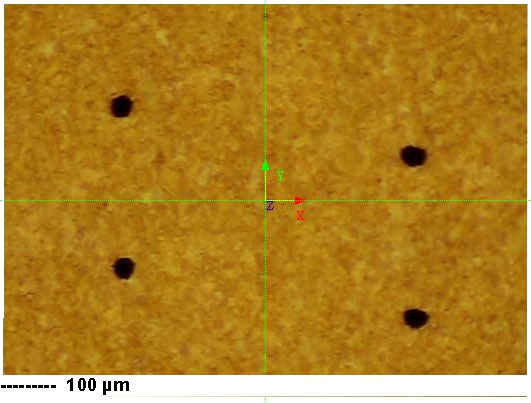

Mikroperforationscluster

Lochgrößen bewegen sich dabei im Durchmesserbereich von 50 nm - 80 µm bei Lochsequenzen von 1.5 – 16 Million Poren pro Sekunde. Zonenanordnungen sind in Breiten von 2 bis 6 mm bei Porendichten von 120 - 250 Poren/cm2 erreichbar, wobei Flächenperforationen oder so genannte Nano- oder Mikrocluster Lochdichten bis zu 3 Million Poren/m2 oder 300 Poren/cm2 generieren.

Die so erzeugten elektrostatischen Mikroperforationen ermöglichen Porositätsbereiche von 80 bis 2500 C.U. ( Coresta Unit ml/2cm2/min ) oder respektive 30 – 6 Gurley bei Materialbreiten von 100 bis 2000 mm und Bewegungen bis zu 500 m/min, abhängig vom Luft- oder Gasdurchsatz und Materialkonsistenz, welche die Perforierbarkeit bestimmt. Mit zwei oder drei Multisektionen von elektrostatischen Mikroperforationseinheiten und simultanen Doppelmaterialbahndurchlauf innerhalb jeder Sektion lassen sich Produktionsausbringungen je nach Materialart, Flächengewichten und Perforierfreudigkeit von 1000 bis 4000 Tonnen pro Jahr erreichen.

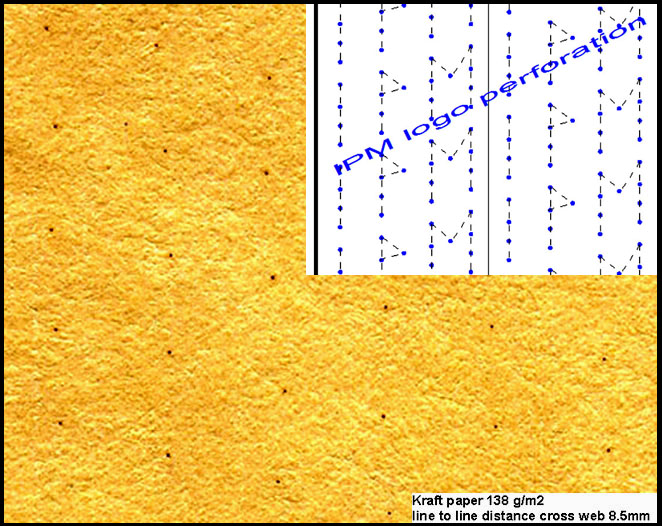

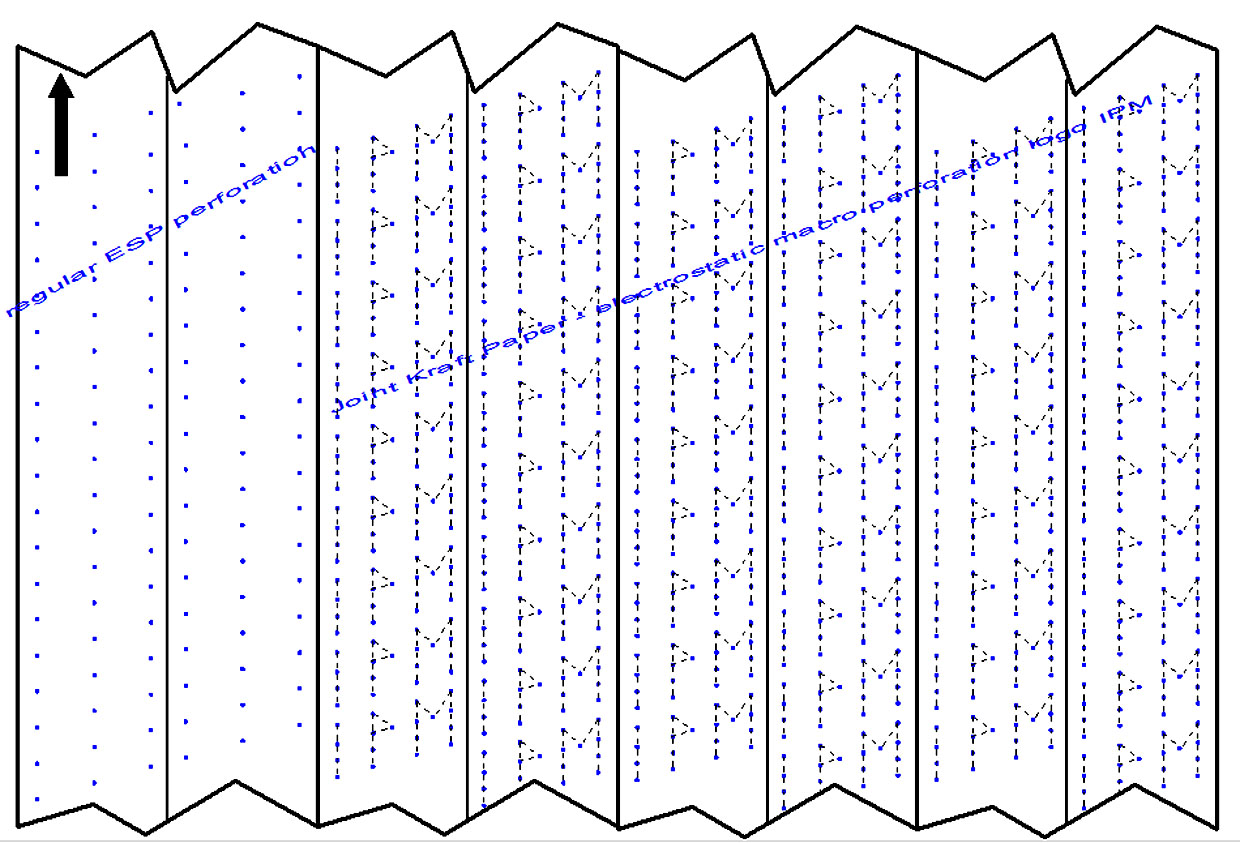

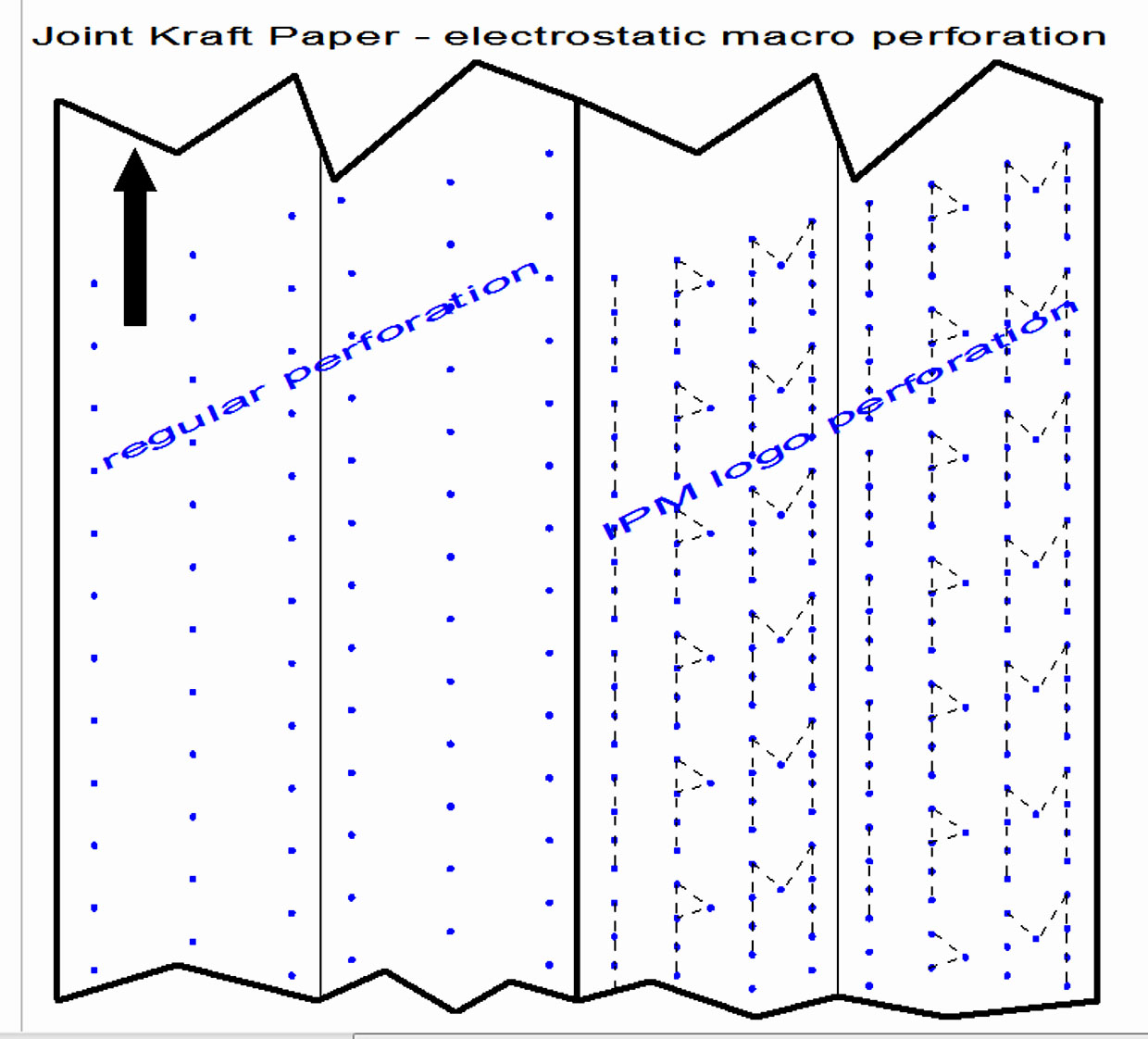

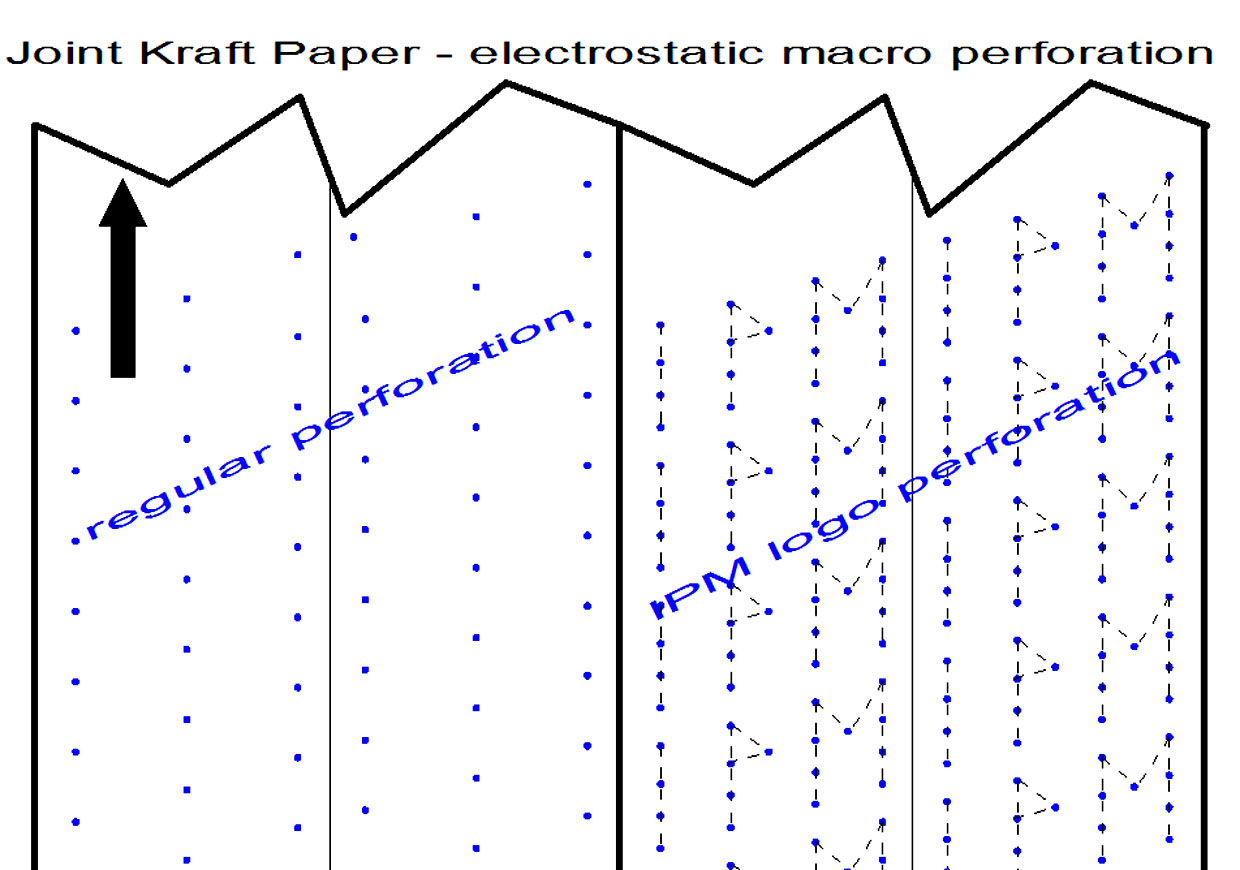

Joint Kraft Paper mit elektrostatischer Makro Perforation, erzeugten company Logo, Scripts oder anderen Zeichen

Produktanforderungen

Grundsatzforderungen für Produktapplikationen mit Verbundstoffen, Vliesstoffen oder Verpackungsbahnen welche Notwendigkeiten von Gas- oder Wasserdampfdurch- aber Wasserundurchlässigkeiten verbunden sind, fordern den Einsatz der elektrostatischen Nano Mikroperforation regelrecht heraus, da Wasser oder andere Flüssigkeiten die relativ kleinen Nano- oder Mikroporen von z.B. kleiner als 0.5 - 5 µm Durchmesser aufgrund der hydrophoben Oberfläche das Produktmaterial nicht penetrieren kann.

Diese und weitere physikalische Vorteile der kleinen Poren und hoher Dichte lassen ermöglichen einen vorteilhaften Industrieeinsatz, da Erfüllungen zur Atmungsforderung und Wasserdampfdurchlässigkeit z.B. nach den ASTM E96-80 oder E96-84 Messmethoden mit 100 – 800 g/m2/Tag mit Laserperforations- oder anderen Prozessverfahren nur äußert schwierig und technologisch aufwendig machbar, zu teuer, zu unwirtschaftlich oder bei derart hohen Lochdichten technologisch keinesfalls erreichbar sind.

Anwendungen

Elektrostatisch Nano oder Mikro perforierte Verbundstoffe, Packmittel oder Folienverbunde verschiedenster Art lassen sich beispielhaft für folgende Produkte und Applikationen verwenden.

atmungsaktive Wanddekorationen mit Beschichtungen oder PVC Verbunden Wandtapeten, Vinyl, Dekore oder andere PE beschichtete Auflagen Fugen- oder Kantenbänder zum Verkleben von Gipsplatten für den Innenausbau Kanten- oder Eckenschutzkraftpapiere mit Luftblasendiffusion des aufgetragenen Klebers Vliesverbunde mit dünnen PE Schichten zum Außengebäudeschutz und Gasaustausch von Holzhäusern Unterdachspannbahnen aus Verbundmaterialien mit Gewebeeinlagen zum Gasaustausch zur Vermeidung von Kondenswasserbildung atmungsaktive Overalls oder Einmalberufskleidung aus dünnen PE Vliesen PE beschichtete Papiere für Füllgutsäcke, Granulate, Gipstüten, Zementsäcke, Tierfutter oder andere Verpackungseinheiten, die einen Luft Auslass zur vorteilhaften Befüllung oder Warengutbelüftung zur Lagerung benötigen Biotope, Gewässer mit Sauerstoffanreicherung Bekleidungseinlagen oder inlet mit atmungsaktiven, komfortablen Trageeigenschaften Seifen, Deo, Hygiene, Hautpflegemittel, Babypflege oder body care Produkte oder Verpackungsstoffe mit Duftstoffsuggerierung und Indikatoren als Marketinginstrumente Trage-, Gemüse- oder Blumenverpackungen aus Papier oder Papierersatzverbundstoffen mit Gasaustausch Brot-, Brötchen-, Früchte-, Lebensmittel oder Nahrungsmittel aus Papierverbundstoffen zur Erhaltung der Frische und Aromas technische Industrieverbundfolien oder Papierersatzmaterialien für industrielle, medizinische, biologische Filtrationszwecke Nano Filtration, Mikrofiltration, Nano Membrane, Mikromembrane, Batterie Separatoren Bioanalyse, Alkoholfiltration, Flüssigkeitsfiltration, Medizintechnik, Analysetechnik, Labortechnik, Agrarwirtschaft

Produktvorteile

signifikante Reduktion von Sack- oder Beutelbefüllungszeiten um bis um 100 % attraktive Luftdurchsatzbereiche bei 200 - 500 C.U. oder 14 bis 3.5 Gurley unveränderter Außenschutz des Verpackungsproduktes Luft Auslass ohne Beeinträchtigung verpackter Produkte und deren Eigenschaften uneingeschränkte Erhaltung der Barriereeigenschaften Duftindikation und Suggestion für den Käufer ohne die Packung zuvor zu öffnen Atmungsaktivität von Wandtapeten oder Wandverkleidungen zur Vermeidung von Schimmelbildung und Fäulnis Brotpapierverpackungen zur längeren Haltbarkeit Aroma- und Frischeerhaltung, Haltbarkeitsverlängerung, Pflanzenabdeckungen Förderung und Verlangsamung von Wachstumsprozessen Gemüse, Früchte und andere Produktgeschmacksentwicklungen innerhalb der atmungsaktiven Außenhülle Atmungsaktivität und Tragkomfort von Bekleidungseinlagen oder inlet keine innere Schweißbildung bei Einwegbekleidung, Lackier- oder Kesselanzügen Unterdachspannbahnen zum Luftaustausch von Innen nach Außen zur Verhinderung von Tropfsteinhöhleneffekten Reinigungs- und Abscheidungsprozesse mit Membrantechniken Blutkörper, Partikel- und organische Filtration für medizinische, biotechnische und industrielle AnalysenPerforationsbeispiele Verpackungsbahnen

Berechnungen für Flächenperforationen

Grundformeln zur praktischen Auslegung einer Anlage

Formelzeichen

Berechnungsbeispiel

Zusammenfassung

Nur die elektrostatische Mikroperforation ermöglicht durch fein dosierte Energieeinkopplung und Funkenkanalerzeugung eine nano oder mikrofeine Ventilation für Packmittel mit erhaltenen Barriereeigenschaften, Schaffung von Atmungseigenschaften für Domestik- und Massenprodukte, industrielle oder medizinische Nano oder Mikromembranen mit Mikrocluster, Vliesstoffe und insbesondere Papierbahnen verschiedenster Art bei relativ großen Bahnbreiten und Transportgeschwindigkeiten, welche aus physikalischen oder prozesstechnischen Gründen nicht mit anderen Verfahrenstechniken erreichbar sind.

Dieser Trend wird sich für spezielle Produkteigenschaften und Anwendungen fortsetzen. Die state-of-the-art, industrietaugliche und im Dreischichtbetrieb zuverlässig arbeitende Nano Mikrocluster Perforationstechnik, deren Integrationsmöglichkeit in vorhandene Umroller- oder sonstige Bahnlauf- und Materialbewegungsanlagen sowie auch als völlig eigenständig arbeitende Produktionsmaschinen möglich sind, wird zukünftig neue Anwendungsbereiche erschließen und Produkte mit besonderen Eigenschaften entstehen lassen.

Durch Weiterentwicklungen von hybriden, modularen Schaltungstopologien mit IGBT, MOSFET, FRETFET oder HVFET zur Erzeugung stromgesteuerter Hochspannungsentladungsimpulse im Zeitfenster von 10 ns bis 15 µs und Pulsendladungen von 0.1 bis 3 mJ hat die Nanotechnologie und Submikroperforation auch im Bereich der Feinpapierveredelung und Verpackungsstoffverarbeitung Einzug gehalten. Auf die anderen zuvor genannte Applikationsbereiche ist dies für die beschriebene Mikroclustertechnologie übertragbar.

Details http://www.microperforation.com/igbt-esp-unit.html

Kunststofffolien wie PE, PP, PVC, LLDPE, BOPP, EVA, MVA, MOV, MOH, FEP, HDPE lassen sich auch zukünftig besser mit hot oder micro needle oder anderen mechanischen sowie mit Gasendladungs- oder Festkörperlaser gesteuert perforieren. In diesem weiten Applikationsspektrum ist es denkbar auch dahingehend entwickelte, angepasste Laserperforationssysteme für Breitbahnen bis zu 2000 mm und Lochsequenzen über 3 Mil./Sek. einzusetzen.

Laserperforationstechnik

Durch Polygon um gelenkte oder gepulste, fokussierte Laserstrahlen bei vorzugsweise 10.6 µm Wellenlänge sind mit im internationalen Markt angebotenen Anlagen Lochgrößen von 60 µm - 200 μm bei Lochdichten von typischer Weise 10 – 30 Löcher/cm, Lochsequenzen von 100.000 bis 300.000 Löcher pro Sekunde, bei maximal 16 oder 32 Laserlochreihen über die Materialbreite verteilt, realisierbar. Damit genierte Luftdurchlässigkeitsbereiche betragen 100 – 3000 C.U. bei Materialbreiten in der Regel von 100 – 500 mm bei relativ hohen Bewegungen bis 10 m/Sekunde, abhängig von verschiedenen Parametern.

Laserperforationstechniken von IPM

Mit Entwicklung des patentierten IPM Dual Hochleistung Lasermultiplexers und optischen Eingangsleistungen bis zu 8 KW, bei fast oder slow flow sowie SLAB Laserquellen mit 10.6 μm oder auch anderen Wellenlängen, ist es erstmalig möglich, bis zu 200 separierte optische Laserstrahlausgänge zu realisieren, mit denen unter anderem auch Mikroperforationen und anderen Bearbeitungen wie Schneiden, Schweißen, Bohren, Abtragen, Trennen, Fügen, Vergüten, Polieren usw. in Breitformaten und Substraten bis zu 5000 mm machbar sind.

Dies sowohl in Kunststoffmaterialien, Folien, Papier wie auch in Stahl, Edelstahl, Aluminium, Keramik, Solarzellen, Glas, Kupfer, Messing, Gold, Silber, Silizium, Blei, Bronze, Druckguss, Werkzeugstählen, Holz usw.

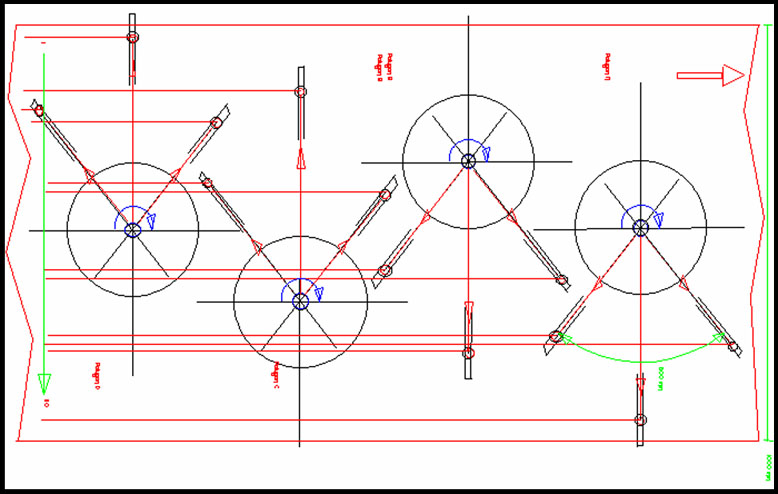

Hierbei werden im auf zwei Ebenen aufgebauten optischen Dualmultiplexer mit hoch rotierenden Doppelstrahlteilern bis zu 200 Lasereinzelstrahlen erzeugt und über flexible Hohlfasern dem Bearbeitungsort zugeführt, deren exakte Positionierung ein automatisiertes Robotersystem und motorgesteuerte Mikro Fokussierung beinhaltet.

Bei diesem Lasermikroperforationssystem sind jetzt Lochsequenzen bis zu 2 Millionen pro Sekunde, Lochgrößen von 60 µm - 100 µm, Lochdichten von typisch 10 – 30 Löcher/cm, Porositäten von 100 - 1000 C.U., Geschwindigkeiten bis zu 400 m/min bei Materialbreiten bis 2000 mm machbar. Damit ist eine vorteilhafte Basis geschafft, um 25.000 Meter Jumbo Rollen an der Ab- und Aufwicklung non stopp zu veredeln, was 2000 – 3000 Tonnen/Jahr von Lasermikroperforierten Feinpapieren oder anderen Verpackungsverbundstoffen an der high tech Automation geführten Produktionsmaschine LPM-1 bei geringen Papierausschuss von kleiner 1% mit Qualitätszertifizierung einer jeder Produktionsrolle ermöglicht.

Hierbei ist das patent angemeldete, optische online Permeabilität Prozessmesssystem OPSS-1 in traversierender Ausführung zur präzisen Positionskontrolle aller Laserperforationslinien sowie der moderaten Erfassung aller Porositätsprofile ein integraler Bestandteil der ISO Qualitätskontrolle und Datenauswertung zum Ende einer jeden Produktionsrolle.

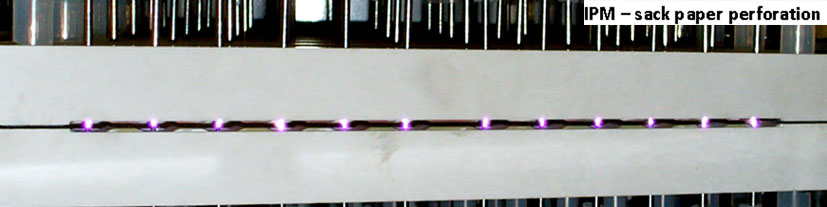

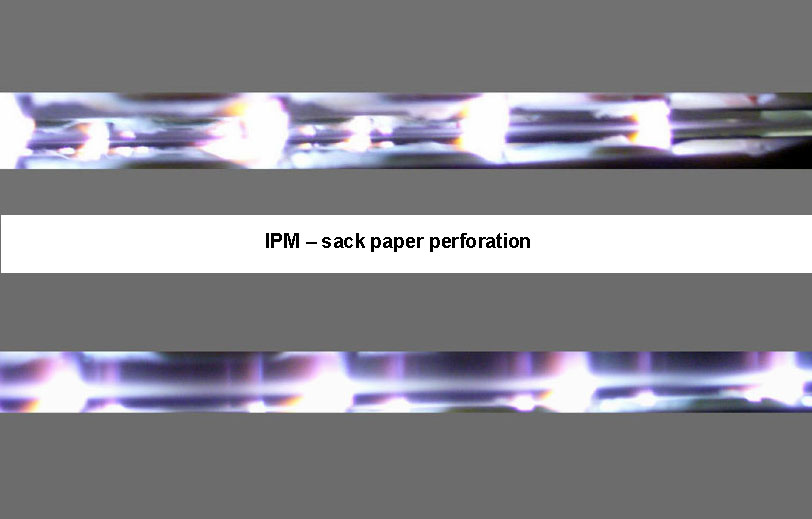

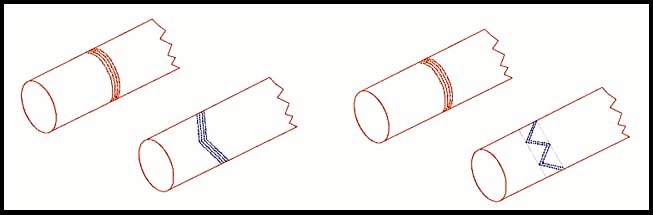

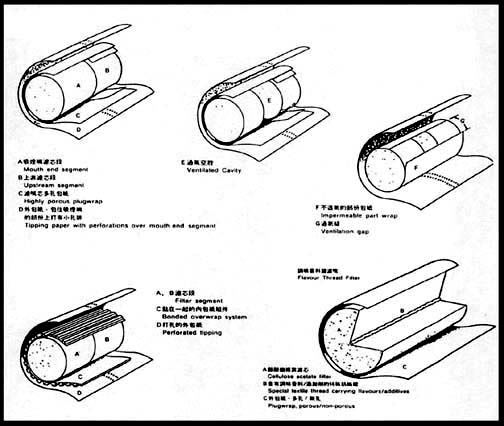

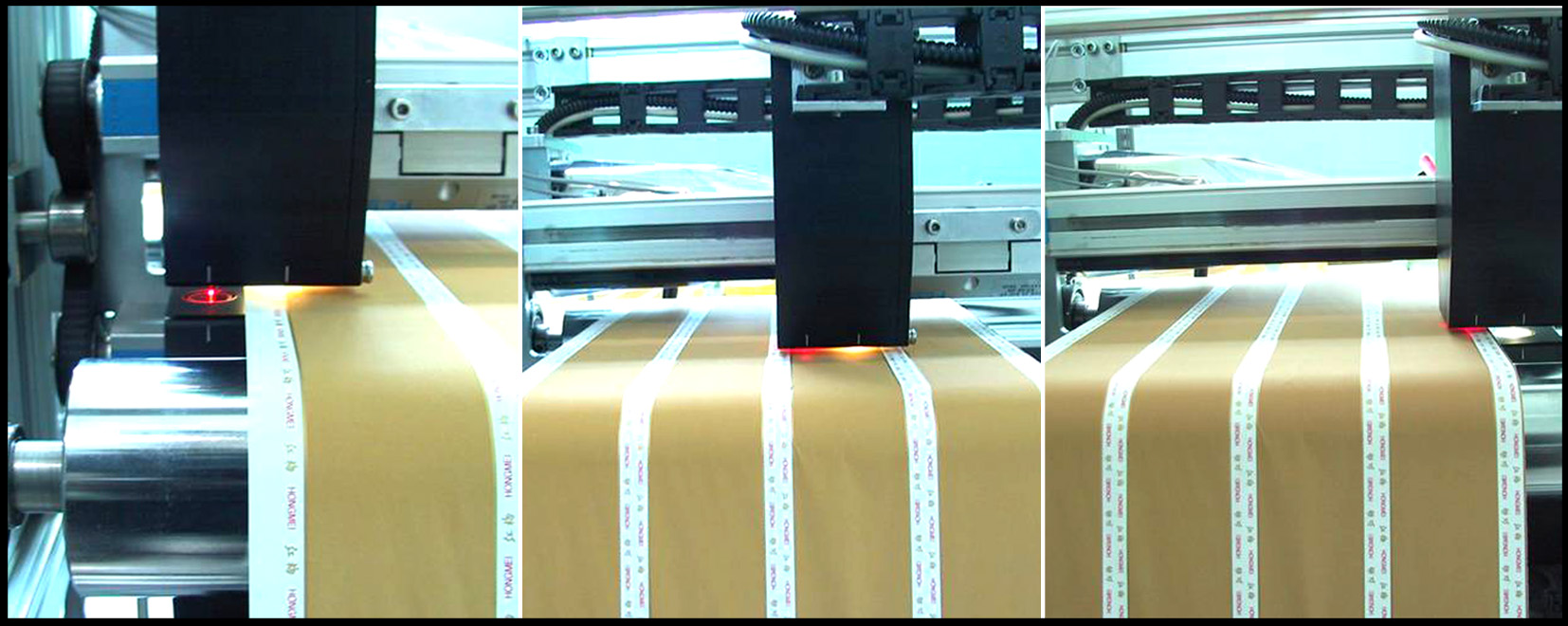

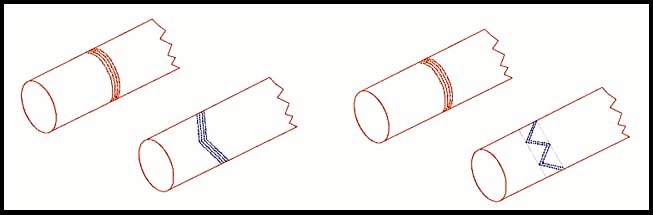

Eine weitere, zum patentangemeldete Entwicklung stellt die Mikro-Laser-Line Perforations- und Strahlauslenkungstechnologie MLL-1 dar, welche einen nicht geradlinigen Laserstrahlverlauf und damit verbundene Lochreihenanordnung auf Materialien ohne Galvanometer oder Piezo Aktuatoren bis zu 2000 Hz ausführt. Breite Anwendungen finden sich z.B. für Mundstückbelagpapierblättchen der Zigarettenfilter, RYO, MYO, usw. gegenüber den von seit mehr als zwei Jahrzehnten traditionell stets koaxial verlaufenden Laserperforationen.

In Sicherheitspapieren, Banknoten, Reisepässen, hochwertigen Geschäftsbriefbögen, graphische Papiere, Hologramme, Broschüren, Buchdeckeln, Geschenkkarten, Geschenkartikeln, Kundenkarten, ATM Kreditkarten, Zugangscodes, Kontrollkarten, Herstelleridentifikation, Produktverfolgung, OEM Garantie, Typenschilder, Deklarationen, Firmenpräsentationen und hundert anderen Plastikfolien, Kunststoffe oder metallischen Materialien lassen sich wellenförmige, Zickzack, Rechteck, Dreieck, gewundene Lochreihenlinien, Firmenlogos, Kryptogramme, Scripts, anti counterfeiting Indikatoren, Merkmale, Identifikationen oder andere beliebige Ausführungsformen als Oberflächengravuren, Materialritzungen, Materialabtragungen, Imbedding oder Mikroperforationen dauerhaft mit zeitlich sehr schnell, präzise aus gelenkten Laserstrahlen einbringen.

Für Lasermikroperforationen mit Co2 Laserquellen ist dies bei Lochgrößen von 60 µm - 120 µm, Lochdichten von typisch 10 – 30 Mikrolöchern/cm bei Lochsequenzen von 100.000 - 300.000 Löcher/Sek. und Permeabilitätsbereichen von 100 – 800 C.U. realisiert.

Details http://www.microperforation.com/lpm-1.html

Details http://www.microperforation.com/mll-1-laser-perforation.html

Ventilation von Massenprodukten

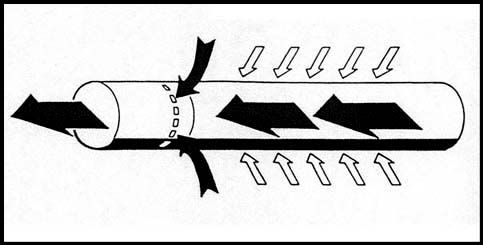

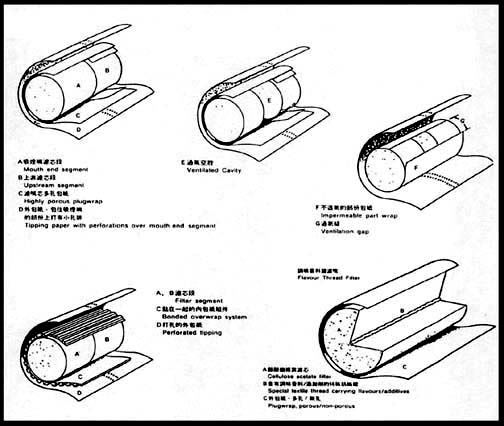

Die

elektrostatische Mikroperforation ist seit 30 Jahren zur Ventilation

von wenigen Nichtfilter- und jetzt für fast alle im Markt

befindlichen Filterzigaretten eingesetzt, um gesteuerte Luft Bypass

Eigenschaften, dem so genannten Lindströmprinzip, zu erzeugen.

Hierzu wird das Zigarettenpapier für wenige

Nichtfilterzigaretten z.B. auch Roll-your-own RYO und bei fast allen

Filterzigaretten das Mundstückbelagpapier, dem so genannten

Tipping aber auch das Plug-Wrap Papierblättchen,

elektrostatisch im Offline Verfahren Zonen Mikro perforiert, um

gewünschte Poren im Durchmesserbereich von 10 - 70

µm generieren.

Oder mit fokussierten Laserstrahlen in Offline Verfahren Lochreichenperforationen aber auch im Online Verfahren an der Filteransetzmaschine direkt durch das Mundstückbelagpapierblättchen bis in den Zigarettenfilter gewünschte Poren im Durchmesserbereich von 60 - 120 µm einzubringen, um so Nikotin-, Kondensat- und Schadstoffanteile für den Raucher über die gesteuerte Ventilationskombination auf strikt vorgegebene Werte zu reduzieren.

Vor vielen Jahren hat IPM auch zur Online Mikroperforation an Zigarettenherstellungsmaschinen ein Verfahren entwickelt und seinerzeit unter EP0460369 sowie DE4018209 zum Patent angemeldet, welche das Einbringen von Mikroperforationsprofilen über die jeweilige Zigarettenlänge sowie in deren Umfang an beliebigen Stellen des Zigarettenpapiers erlaubt.

http://www.freepatentsonline.com/EP0460369.html

Details http://www.microperforation.com/online-perforation-cigarette.html

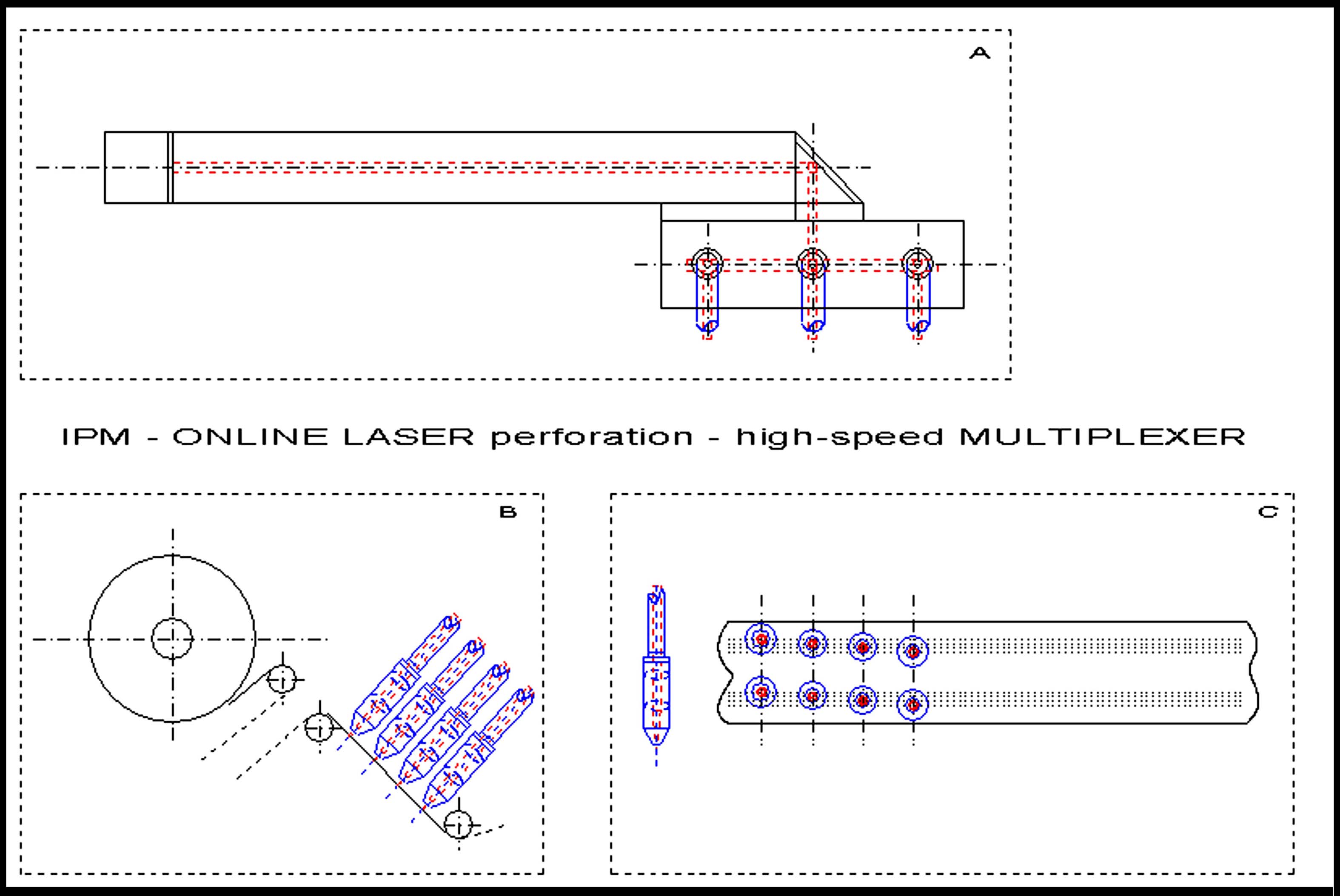

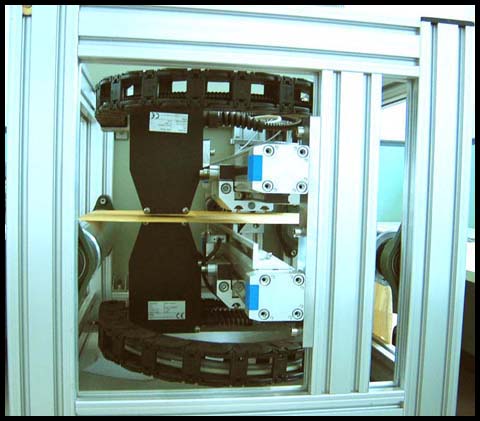

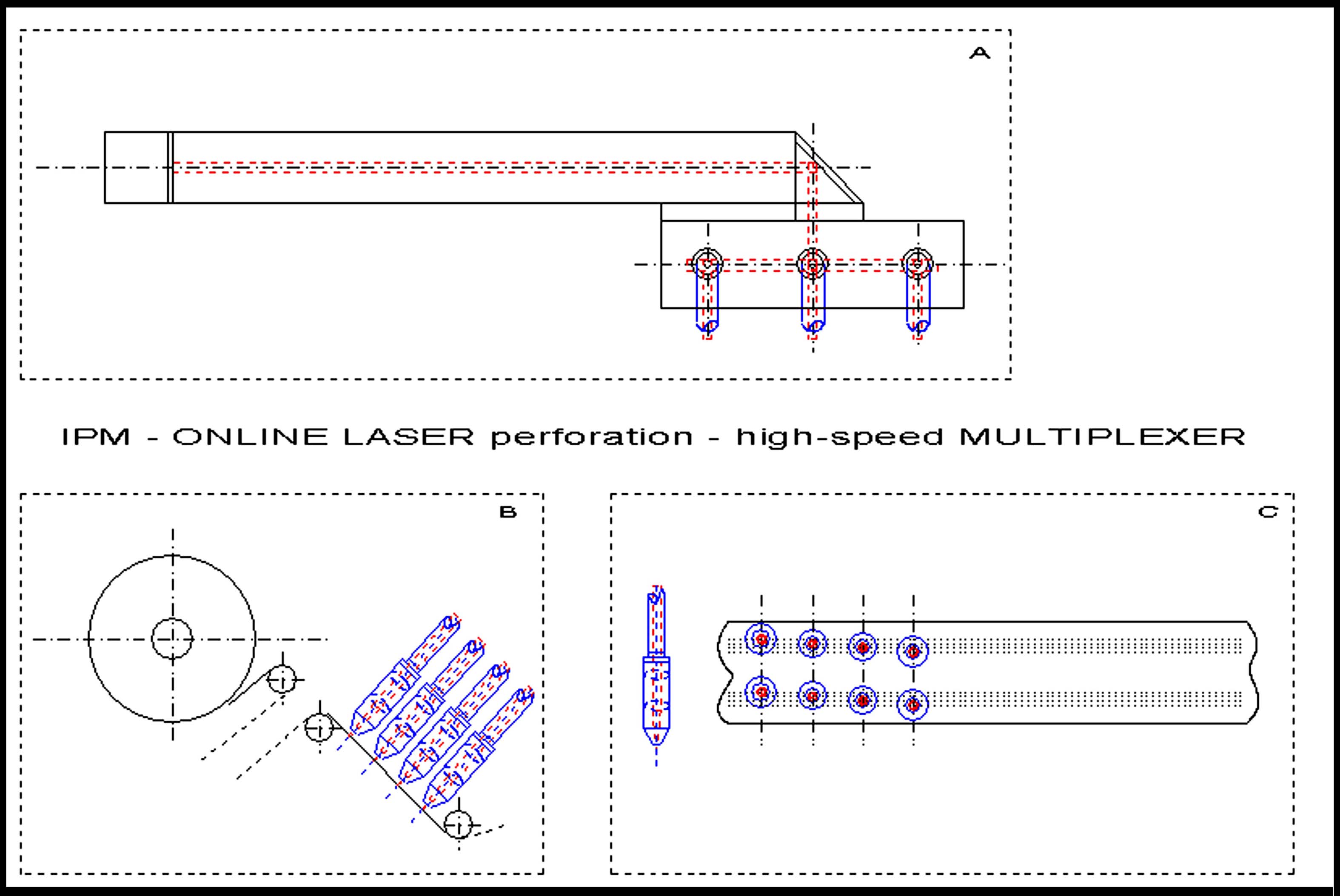

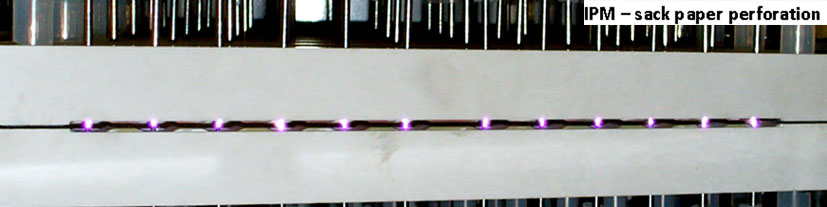

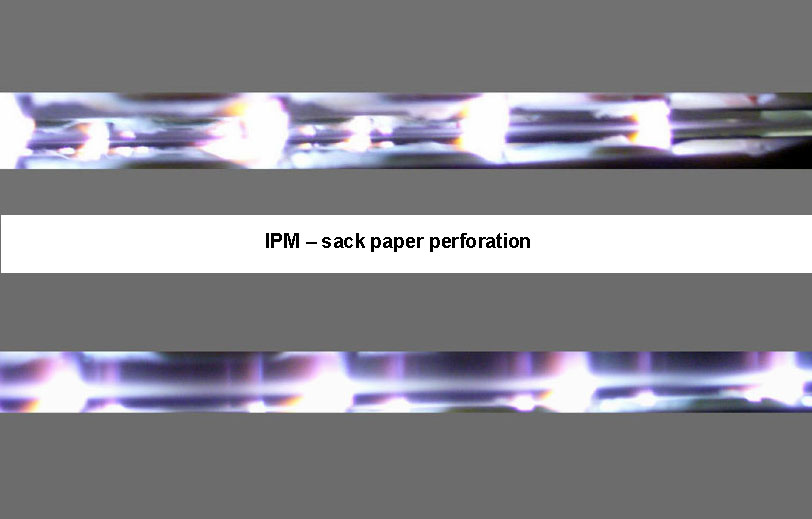

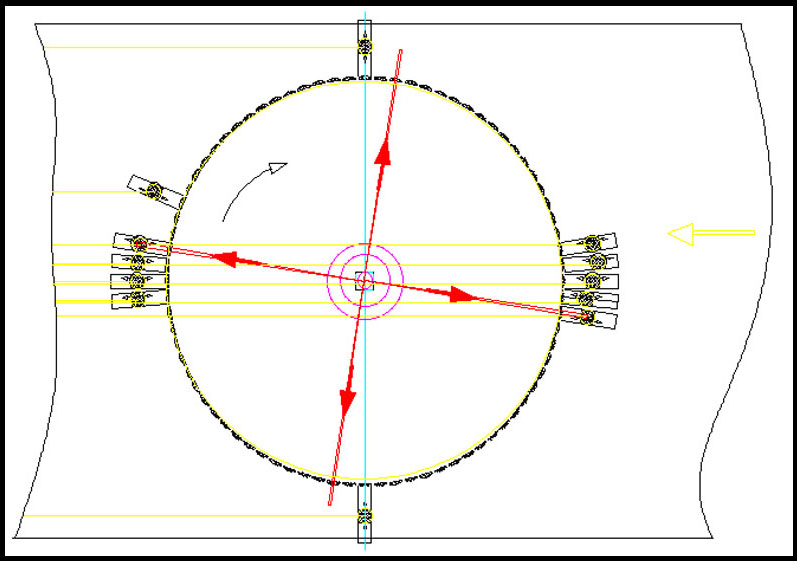

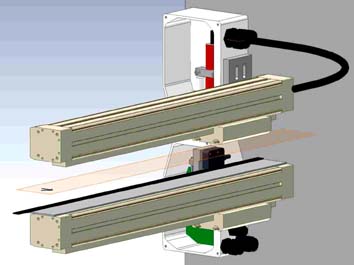

ONLINE LASER PERFORATION with patent grantededed high speed multiplexer DE102004001327

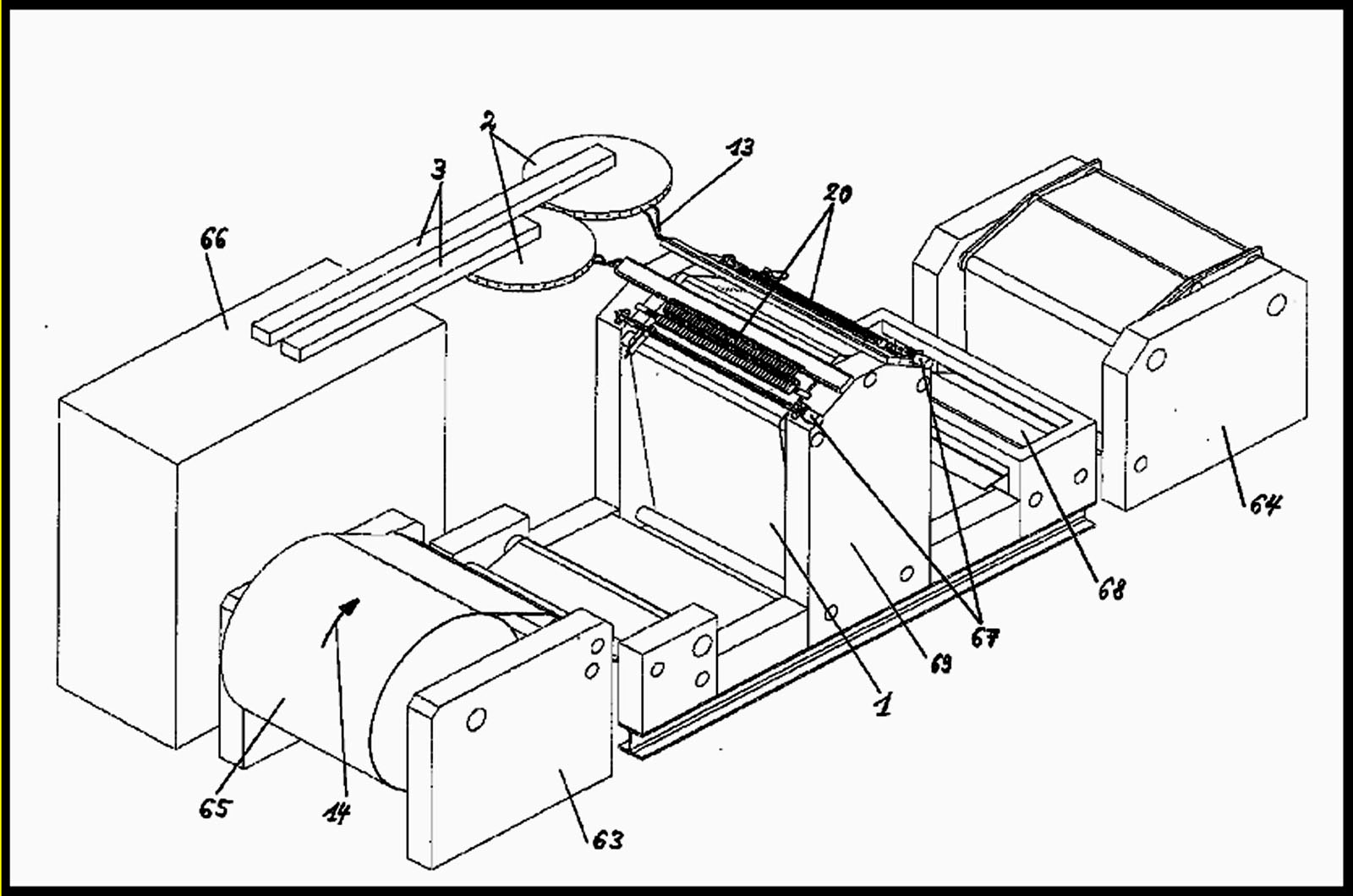

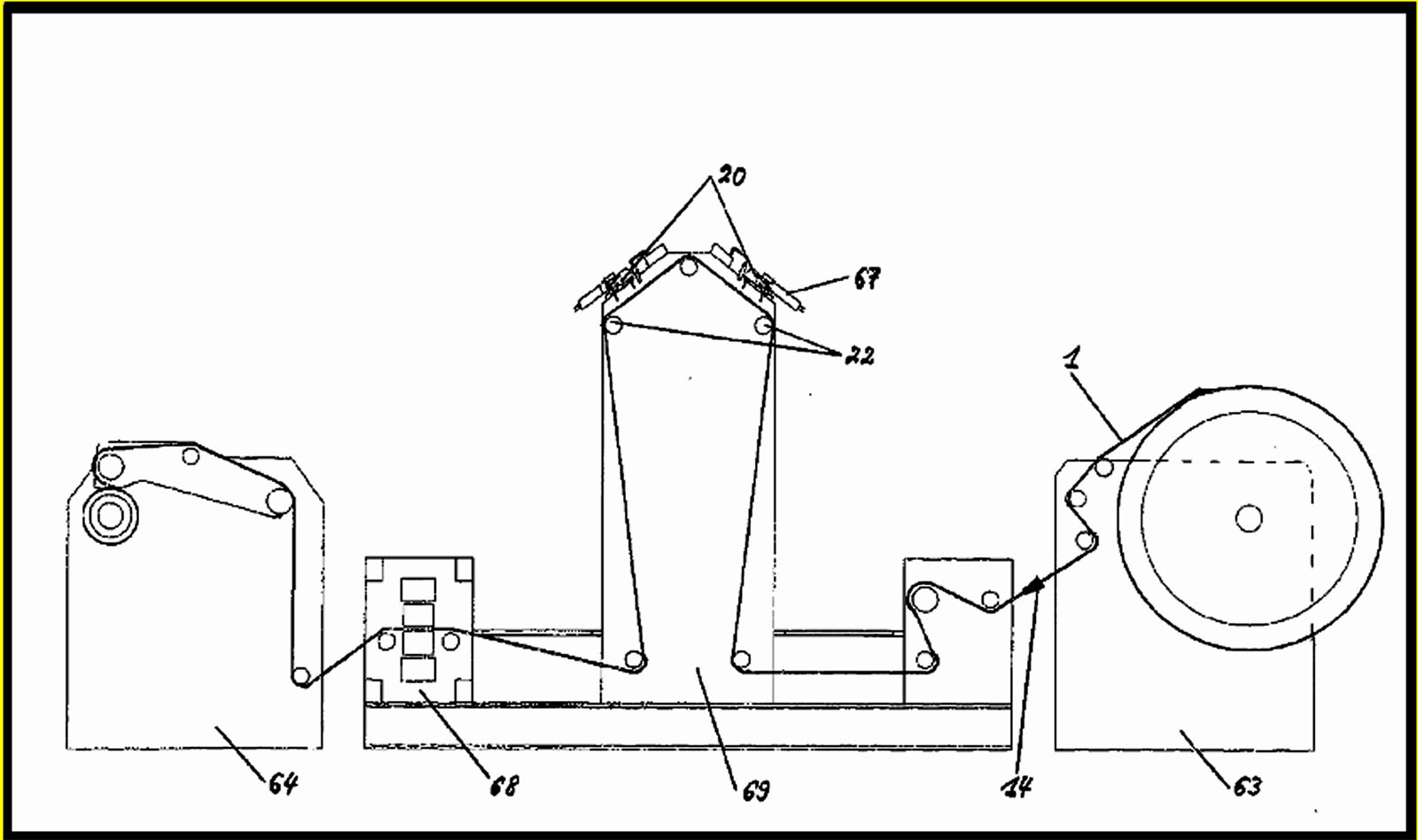

A – laser source and IPM patent granted multiplexer with 8 optical channels

B – bobbin unwinder and perforation heads

C – tipping paper strips with 8 laser perforation lines

further information on request

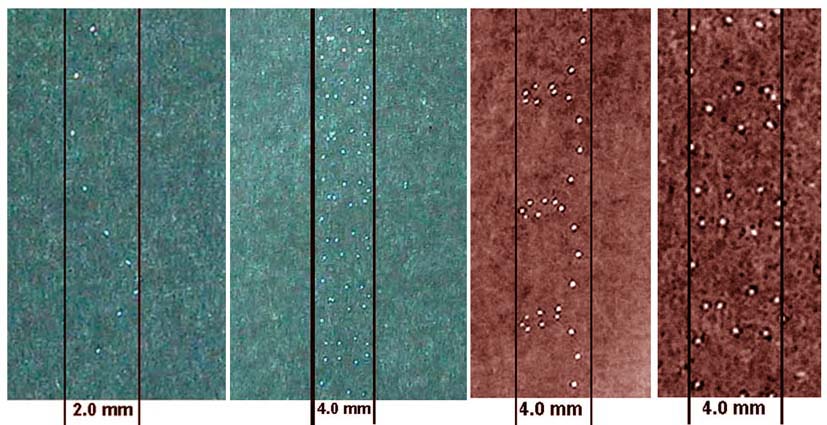

Kontrolle von Nano oder Mikro Permeabilität Cluster

Permeable,

naturporöse, Gas- oder

Wasserdampfdurchlässige, Nano oder Mikroperforierte

Warenbahnen, Verpackungsstoffe oder andere bewegte Materialien bewegen

mit Transportgeschwindigkeiten bis zu 10000 mm/Sekunde bei Breiten bis

zu 5000 mm, so dass sich pneumatische, Über, Unterdruck oder

Jetstream Systeme oder andere Materialberührende

Prozessmessungen als online Kontrolle exorbitant schwierig gestalten.

Des Weiteren haften den Materialberührenden Messmethoden

mögliche Nachteile hinsichtlich Bahnzugserhöhung,

Materialabriebs, Faltenbildung, Undichtigkeit im Sensorkopfbereich,

starken Verschmutzungen, Nichtlinearitäten und anderen

Schwierigkeiten an.

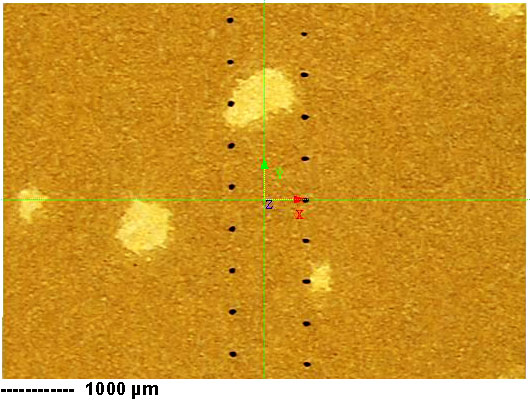

Sensorsystem

Optische online Sensormessverfahren bieten vorteilhafte Möglichkeiten zur spektralen Transmissions- oder Extinktionsmessung für die Bestimmung der pneumatisch statischen Gas- oder Wasserdampfdurchlässigkeit dieser bewegten Materialien, wenn wesentliche Grundkriterien wie z.B. optische Transparenz, Opazität, Spektralverhalten im Bereich von 350 – 900 nm, Porengrößen von 50 nm bis 100 µm, Porencluster bis 500/cm2, Materialdichte, Konsistenz, Glätte, Glanz, usw. erfüllbar sind. Dabei ist das Anforderungsspektrum aufgrund der eingangs genannten Produktkonditionen und online Produktionskontrolle, kleinen geometrischen Porenabmessungen, Gasdurchgängen, relativ hohen Transportgeschwindigkeiten und wichtiger Messwert Reproduktion mit der optischen Porositätsmessung gut zu lösen.

IPM hat verschiedene optische Messverfahren und Sensorsysteme in stationärer oder Traversausführung als OPSS-1 und OPRL-1 entwickelt, im Markt eingeführt und mit der DE10251610 sowie auch in China 200310104764, DE19542289 zur Patentanmeldung gebracht, mit denen online Produktionskontrollen und Produktzertifizierungen nach ISO 9001, 9002 und dem Statistical Quality Control (SQC) im Reproduzierbarkeitsgrad und Genauigkeiten unter 2% praktiziert sind.

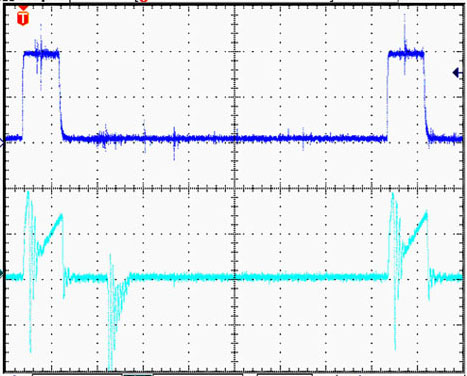

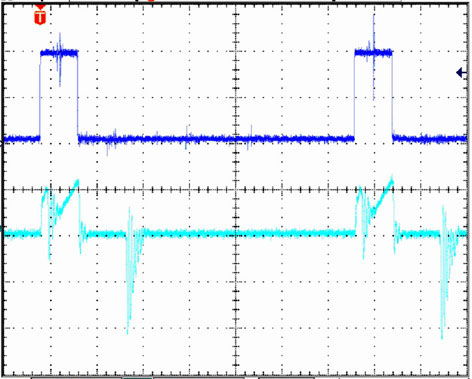

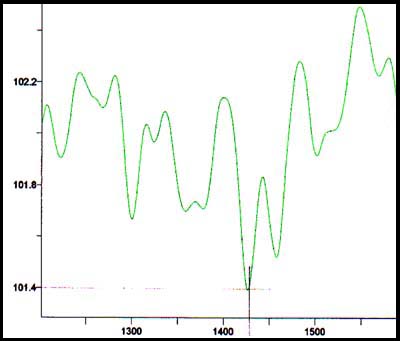

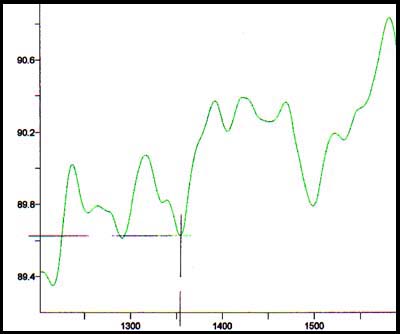

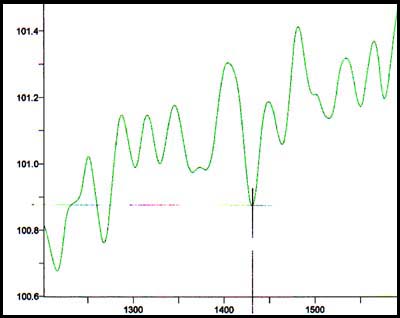

Transmissionsmodus

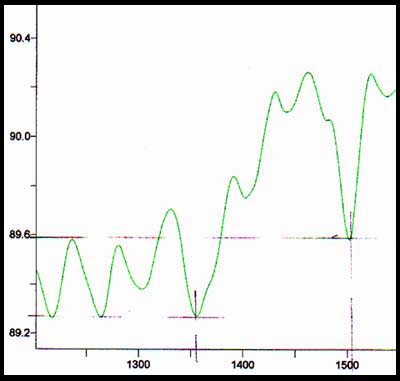

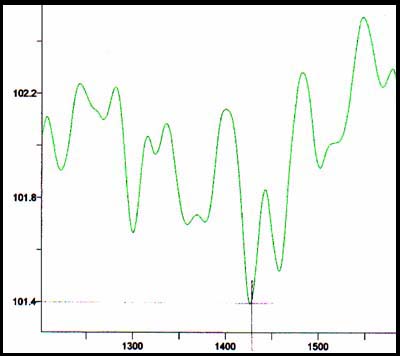

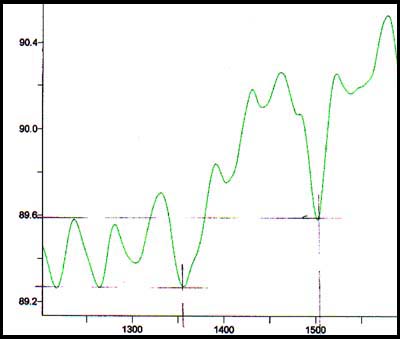

Damit sind Gas- oder Luftdurchlässigkeitsmessbereiche von 80 C.U. bis 5000 C.U. ( Coresta ml/2cm2/min ) oder 100 – 2 Guley in Kombination von hybrid Multifarb- und Intensitätssensoren, Permeabilitätsprofilerfassungen mit Auflösungen kleiner 0.1 mm mittels integriertem Präzision Linienlaser, CCD Zeile, intelligente DSP und FPGA Multicontroller Sensorelektronik, Firmware, RS 232, RS 485 high speed Links oder CAN, Profibus, Ethernet Busanbindungen bei scanning speeds von 20 bis zum 1000 mm/Sek. ober- und unterhalb des relativ dazu bewegten Materiales im Transmissionsmodus realisiert.

Der angekoppelte Industrie PC und deren Prozesssoftware kommuniziert mit dem OPSS-1 Sensorkopf, steuert gleichzeitig die Travers Achse und deren controller und übernimmt ebenfalls die Trendnachführung als feed-back close-loop Steuerung zur gravierenden Einengung der Produktmessgröße. Unterhalb der bewegten Materialbahn befindet sich auf gleicher X/Y-Achsenlinie die Beleuchtungszuführung, welche über eine spezielle Lichtfaser der chromatischen Lichtquelle zugeführt. Messspalte in Z-Richtung sind bisher im Bereich von 2 – 10 mm praktiziert, größere Abstände sind auf Anfrage und optische Vortestung der Materialkonditionen denkbar.

Permeabilitätsprofile

Des Weiteren bietet das OPSS-1 Sensorsystem auch die Möglichkeit, nicht nur lokale Permeabilitäten, Nanodurchlässe, Massenporen, Mikrokanäle oder Mikroperforationszonen, stationär kontinuierlich zu messen, sondern auch auf einer travers bewegten Einheit eine Vielzahl sequentiell nebeneinander angeordneten Messzonen, Bereiche, Permeabilitätscluster und Vollflächenbereiche bis Materialbreiten von 5000 mm automatisiert zu detektieren und Messwert gerecht auszugeben.

Andere Messgrößen wie z.B. die WDD nach ASTM oder ISO in g/cm2/h, Liquid, Jet Stream Penetration, Feuchtigkeitsverhalten, Partikelretension, Photonenstrom oder andere physikalische Eigenschaften sind nach entsprechenden optischen Voruntersuchungen möglich, sofern die Materialien eine bestimmte optische Transmission im gemessenen Wellenspektrum aufweisen und das Verhältnis zwischen Nutzsignal und Untergrundrauschen 18 – 28 dB oder besser beträgt.

Optische Permeabilität

Porositätsmessung

Da die naturporösen oder zu perforierenden Bahnmaterialien sich mit Bahngeschwindigkeiten bis zu 600 m/min und in Bahnbreiten bis zu 2000 mm bewegen, gestaltet sich eine pneumatische, also bahn berührende Porositätsmessung, exorbitant schwierig. Hinzukommend sind diese Messmethoden mit Nachteilen der Bahnzugserhöhung, des Materialabriebs, Faltenbildung, Undichtigkeit im Messkopfbereich, starken Verschmutzungen, Nichtlinearitäten und Schwierigkeiten stets verbunden.

Daher bieten sich optische Messverfahren zur Transmissionsmessung als Funktion der pneumatisch, statischen Gasdurchlässigkeit für naturporöse oder Nano, Mikro bzw. Makro perforierte Bahnen an. Dabei sind die gestellten Anforderungen aufgrund der eingangs genannten Produktverarbeitung und online Kontrolle, extrem kleinen geometrischen Porenabmessungen, relativ hohen Bahngeschwindigkeiten und guter Messwertreproduktion mit der optischen Porositätsmesstechnik in idealer Weise zu lösen.

OPSS-1 porosity sensor scanner control - download OPSS-1

Hierzu hat IPM eine Reihe neuer, patenangemeldeter optischer Messverfahren und Systeme in stationärer oder travers Ausführung als OPSS-1 und OPRL-1, entwickelt, weltweit im Markt eingeführt und mit der DE10251610 sowie auch in China unter 200310104764 zur Patentanmeldung geführt.

Details http://www.microperforation.com/opss-1-optical-online-porosity.html

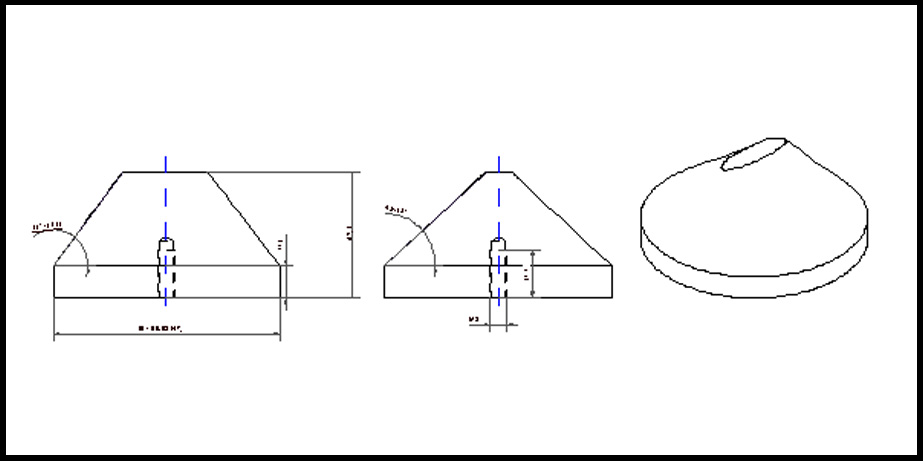

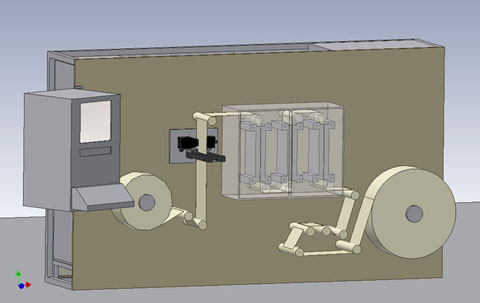

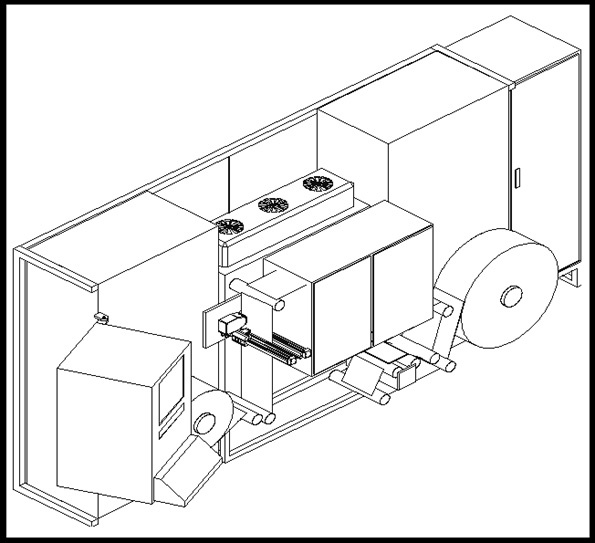

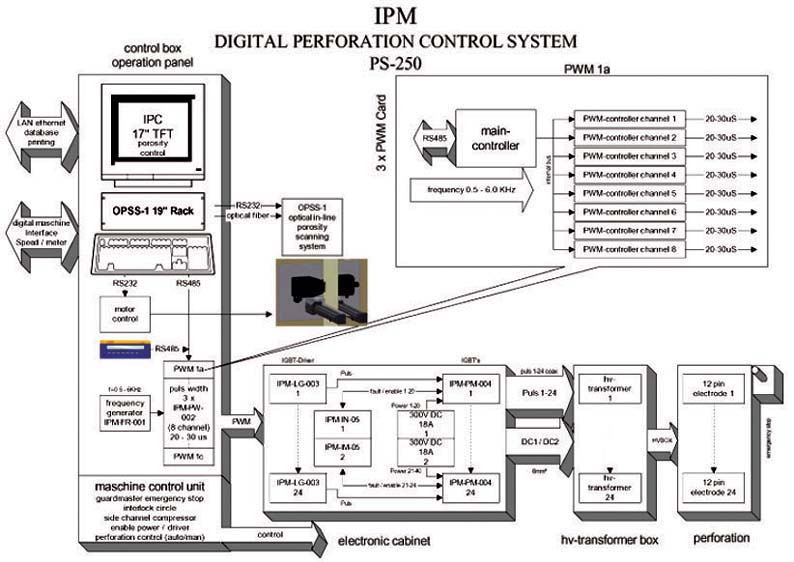

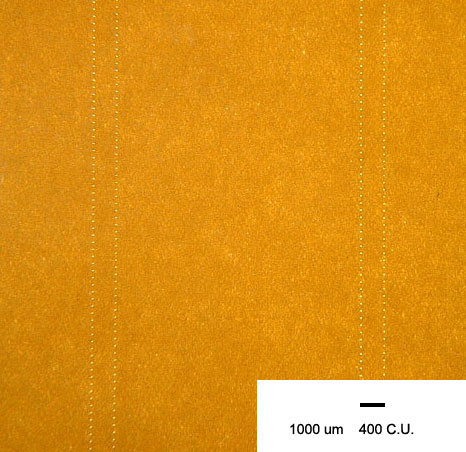

PS-250-4 Quad Bobienen Perforationsmaschine - download PS-250-4

Porositätsmessbereiche von 80 C.U. bis 5000 C.U. mit Multispektral Sensoren, Perforationslochreihenerfassungen mit Auflösungen < 0.1 mm mit Präzisionslinienlaser, Scanning Speeds von 20 bis zum 300 mm/Sek., intelligente Multicontroller DSP Elektronik im Sensorkopf, high-speed RS-232 Link sowie Auswerteeinheiten sichern die qualitative, quantitative online Kontrolle nach ISO 9001/9002 an verschiedenen Produktionsmaschinen.

IPM – International Perforation Management – hat verschiedene Laser und elektrostatische Perforationsverfahren, insbesondere auch für neue Produkteigenschaften, entwickelt, deren Systeme und Produktionsmaschinen weltweit im Einsatz sind.

Zukunftsperspektiven Die elektrostatische ESP Nano- oder Mikroperforation findet vorzugsweise ihre Anwendung in Bereichen der Veredelung von Feinpapieren, Verpackungsbahnen, Vliesstoffen, Non-Woven, Filter-, Sack- oder Kraft- sowie Spezialpapiere verschiedenster Art, insbesondere bei der zusätzlichen Behandlung von Bahnmaterialien zur Erzielung besonderer Eigenschaften, welche aus physikalischen oder prozesstechnischen Gründen NICHT mit anderen Verfahrenstechniken erreichbar sind.

Die state-of-the-art, industrietaugliche und im Dreischichtbetrieb zuverlässig arbeitende ESP Perforationstechnik, deren Integrationsmöglichkeit in vorhandene Umroller- oder sonstige Bahnlaufanlagen sowie auch als völlig eigenständig arbeitende Perforationsmaschinen möglich sind, wird zukünftig neue Anwendungsbereiche erschließen und Produkte mit besonderen Eigenschaften entstehen lassen.

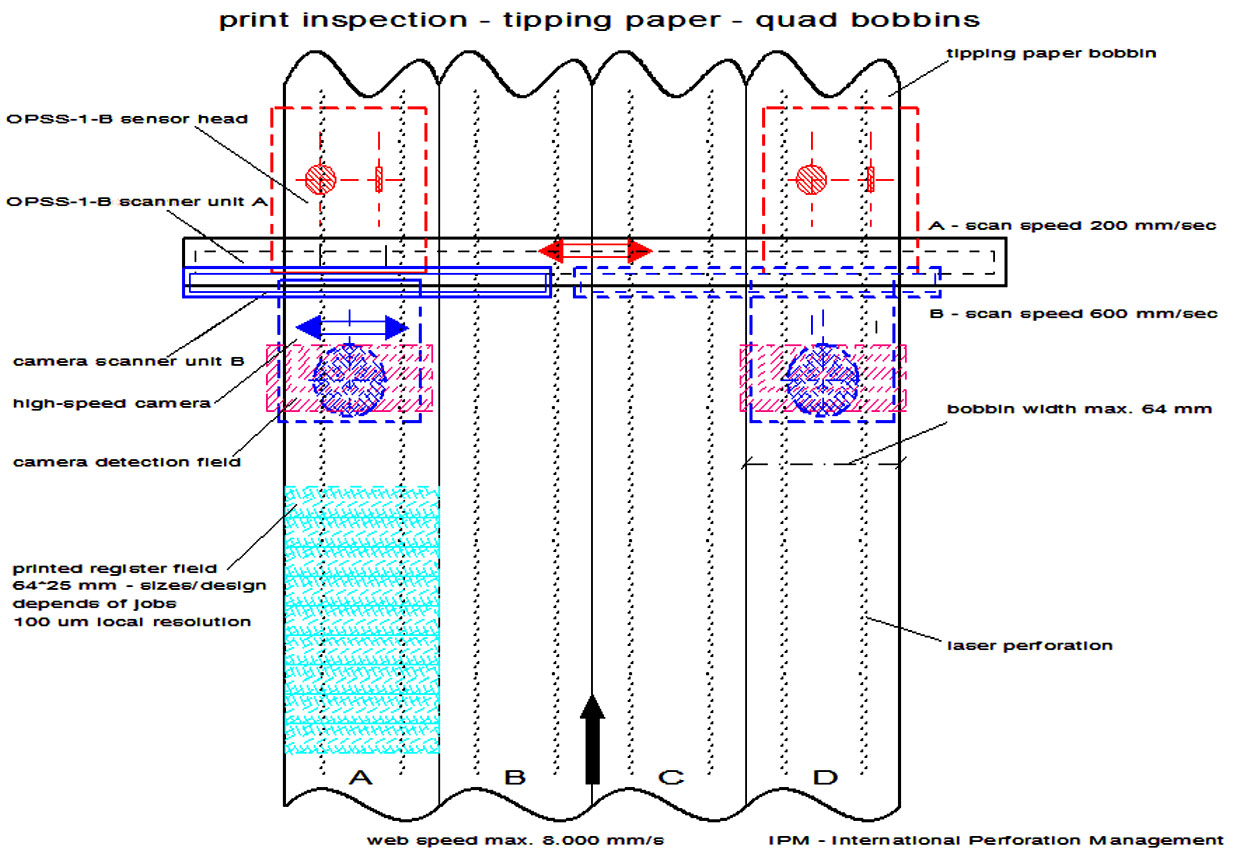

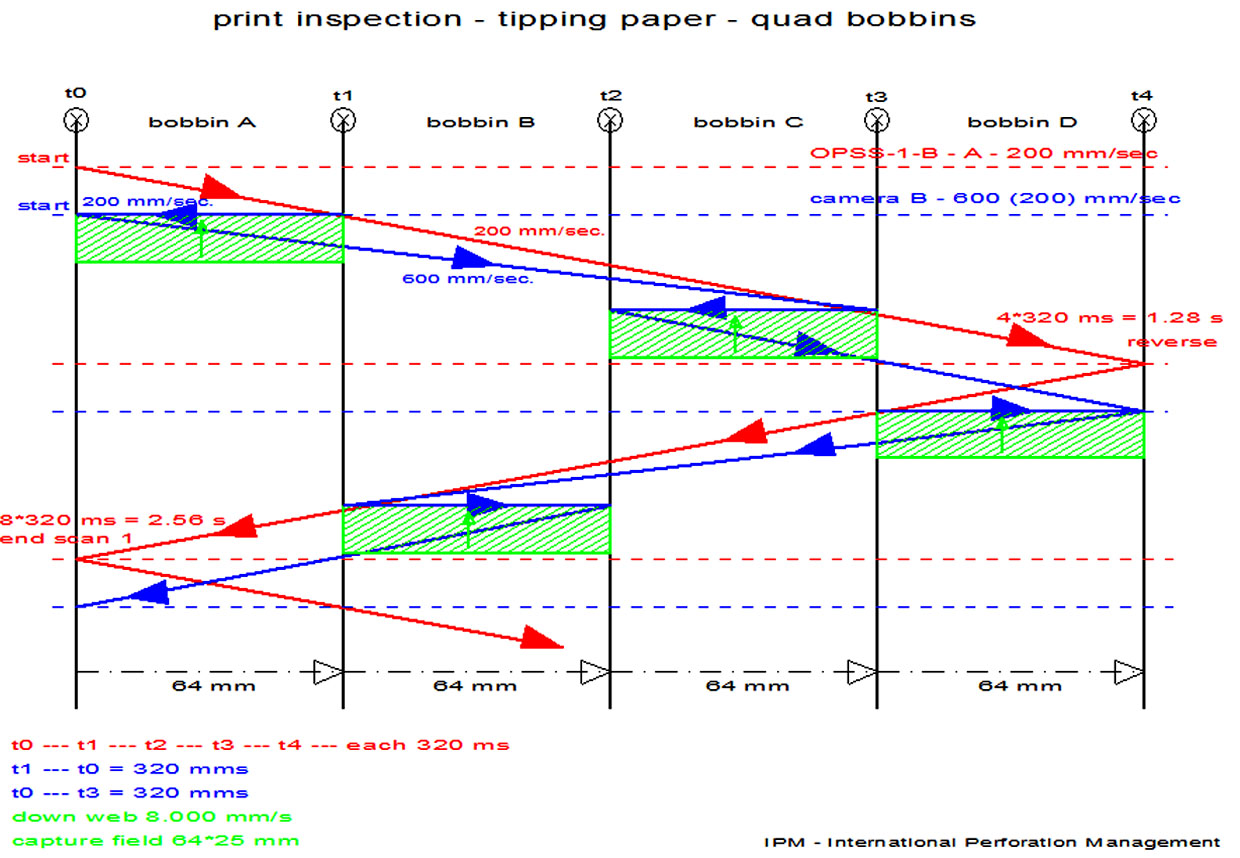

OPSS-1-B Druckkontrolle mit hi-speed Kamerasystem an QUAD Bobienen Laserperforationsanlagen - download OPSS-1-B

Nano Micro technologies - incredible archipelagos of applications

Web material as regenerated cellulose films, filter, cigarette, tipping, roll-your-own RYO paper, transparent, coated special, bag or packing papers, bonded fabrics, spun bonded non-woven, technical textiles, fabrics, laminate with base weights from 20 g/m2 to up to 150 g/m2, up to 20 g/m2 LPDE coating films, are perforated electro statically nano, micro, or by laser (mechanical hot or micro needle) with micro or macro holes for wide range of application purposes.

Electrostatic NANO MICRO PERFORATION, based at micro discharging and sparking, Bluemlein and Plasma Tunnel effects with gas atomic ionization in Nanosecond time windows.

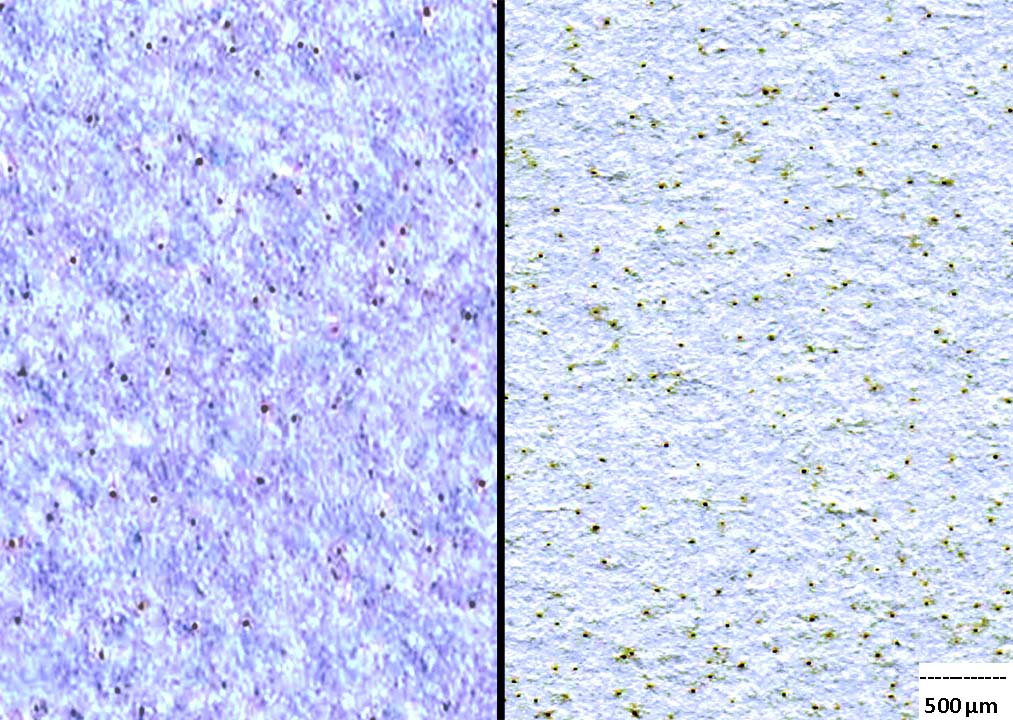

The pores are statistically irregularly distributed with size ranges from 100 nm up to 80 micron diameter and analogically, under LASER or micro macro PERFORATION, arranged in diameter sizes from 60 up 200 micron, at best non-inclined holes und rows of holes of diverse arrangement comprehension.

For the human eye invisible electrostatic nano or micro perforations may be arranged in areas as well as in zones with specific distances within its web. Controlled pore sizes in wide ranges from 100 nm to 80 micron diameters by holes sequences up to 16 million pores per second and 0.1 bis 3 mJ discharge energy for each Pore.

Arrangements of zones are usually carried out in width from 2 to 6mm and pore density of 15 up to 250 pores per cm2 where as the perforation of area results in pore densities of up to 5 million pores per m2. ESP perforations allow porosity levels from 80 to 2500 C. U., web widths from 100 to 2,000 mm at web speeds of up to 500 m/min, depending on porosity and material consistency in relation to its ability to perforate.

PS-250-4 quad bobbin perforation machine - download PS-250-4

PS-1200 wide web perforation machine - download PS-1200

Conventional laser perforation

Possible to perforate by pulsed and focused laser beams are holes sizes from 60 to 200 micron at density of holes of typical 10 to 30 holes per cm length, holes sequences up to 400,000 holes per second at a maximum of 32 hole rows by laser distributed over the width of the web with traditional systems or machines on the market.

Porosity levels from 100 up to 3,000 C. U. by web widths up to 500mm at web speeds of up to 600 m/min are archive able, depending on porosity and material consistency in relation to its ability to perforate.

IPM laser perforation processes

IPM owns development of LASER PERFORATION technology LPM-1, patent granted DE102004001327, operates with quad laser beam input of 8 Kilowatt optical power input ( fast flow or SLAB laser with 10.6 micron wave length ) to an upper/lower dual beam multiplexer to generate up to 200 individual laser perforation beams, rows, lines across the web, combines automatic laser perforation head positioning, focus setting, by web speeds up to 400 m/min, web widths up to 2,000 mm, up to 4,000,000 holes per second. Each laser perforation lines are archive able from 100 up to 2,000 C.U.

Jumbo-roll-by-roll production, optical online porosity vision and simultaneous perforation line positioning control, full feed-back system for constant porosity levels are further features. Each laser perforated jumbo roll is ISO production data controlled, benefit and certificated.

Other industry

areas

The conception of

high power twin laser beam multiplexers enable many possibilities in

other industry application fields as cutting, cut-offs, welding,

surface finishing, drilling, polishing, forming, surface treatment,

roughness improvement.

Each of the 200 single perforation head can be positioned in X directions across the running web or other laser treated material sheet, substrates, blocks etc.

The automatic processes, equipments and devises opening completely new possibilities in industry, science, military or space laser application. Patent grantededed of process and device with DE102004001327.

more details http://www.microperforation.com/lpm-1.html

Other laser features

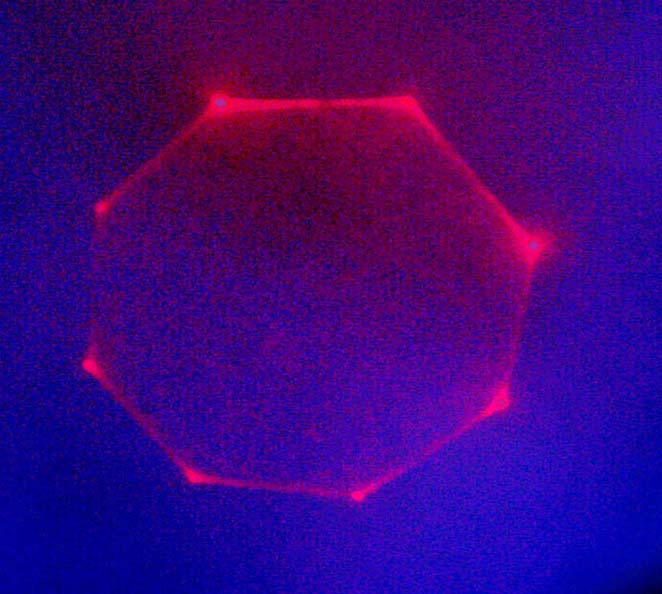

A patent pending Micro Laser Line perforation technology MLL-1 generates sinus, waves, zigzags or other kinds of perforations cryptograms, designs as multiple or quadruple pairs of micro laser lines in web direction. Hole, slot or star sizes in ranges from 60 up to 200 micron are possible. Provide for tipping, cigarette, packaging or other kind of paper, plastic film or other web material.

Special features of micro laser line perforation enables fundamental new product characteristic in scripts, e.g. for mouthpieces with tipping paper, CTP on cigarette filters, product indication with visible perforation holes, brand name, company logo, indications, anti counterfeiting designs, cryptogram, etc.

In addition for other industry, medical, science, defense or military purposes, material and applications fields. Patent pending for process, device and product property DE102004012081.

more details http://www.microperforation.com/mll-1-laser-perforation.html

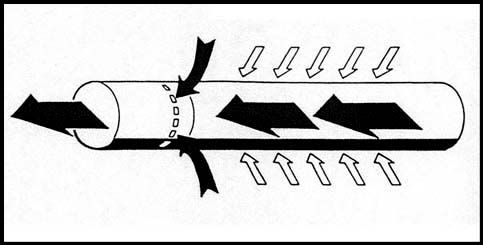

Ventilation of mass products

Electrostatic perforation has been used since 30 years for ventilation of non filter, RYO or filter cigarettes to create a directed and guided air bypass or Lindstroem principle. For this purpose, cigarette paper for some non filter or RYO cigarettes and almost every kind of filter cigarettes tipping papers are perforated electro statically OFFLINE in zones from 2.0 up to 6.0mm width or in rows with ON-LINE or OFF-LINE by use of slow, fast flow, sealed-off or SLAB CO2 gas or diode laser in order to reduce the harmful substances such as nicotine and condensate down to allowed values. Another effect is the possibility to control the degree of ventilation of Cigarettes.

Online micro perforation – porosity profile

Years ago IPM had developed a multiple online electrostatic micro perforation OESP-1 units at cigarette making machines which was patent applied with EP0460369 and DE4018209.

http://www.freepatentsonline.com/EP0460369.html

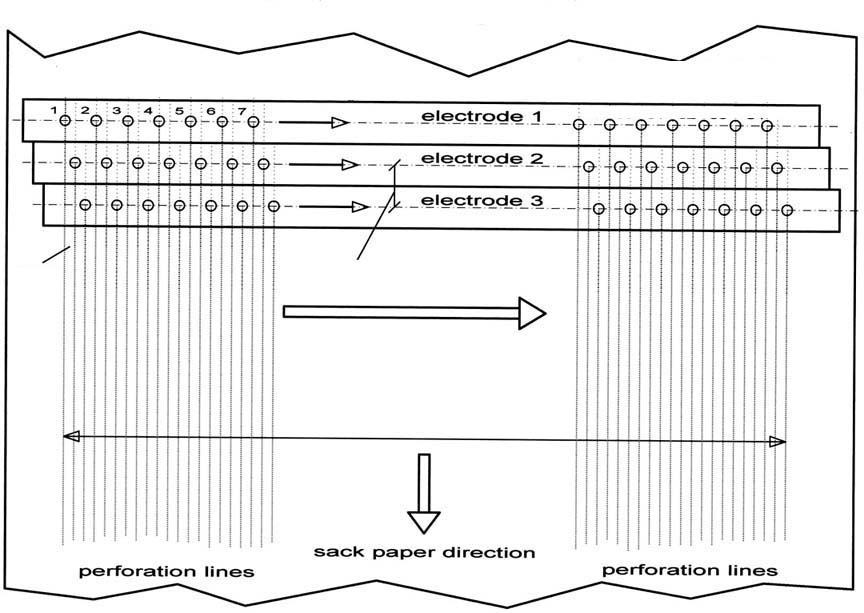

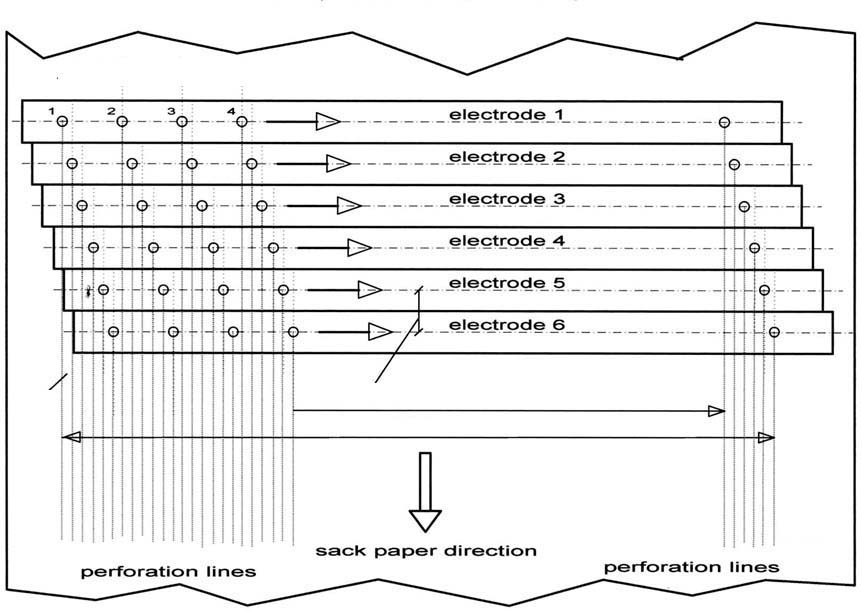

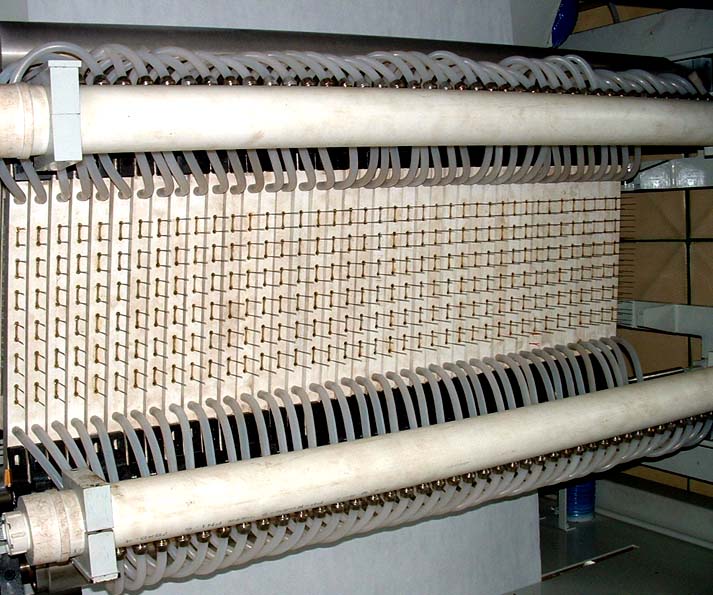

The method and the device for electro-erosive perforation of cigarette paper basically operates with at least two pairs of electrodes which are ignited at the same time in such a manner that each perforation section is treated twice in order to provide a corresponding intensity of perforation, taking into consideration the duration of ignition and the web speed. In particular, the invention operates with at least four pairs of electrodes, between which the web of cigarette paper to be perforated is moved through. The cigarette paper is moved in the longitudinal direction of the cigarette to be produced later, the width corresponding to the circumference of the cigarette plus an overlap section for bonding. Perforating is carried out transversely to the direction of movement, that is to say an accurately defined zone section is produced around the circumference of the cigarette. The pairs of electrodes are arranged at a distance which corresponds to half the cigarette length (a, b, c) when four pairs of electrodes are used.

The first and the third pair of electrodes are ignited simultaneously. A distance dependent control causes the second and fourth pair of electrodes also to be ignited simultaneously when the previously perforated sections have traveled the distance of half a cigarette length. Each section is perforated four times, the speed at which the web (10) can be moved being determined not by the spacing (half a cigarette length) of the pairs of electrodes but by the spacing of the pairs of electrodes in each case simultaneously ignited (one cigarette length). This provides for uniform, intensive and very powerful perforation and the cigarette paper treated can be continuously supplied to the cigarette machine for further processing in the longitudinal direction of the cigarette.

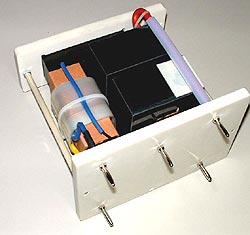

That electrostatic micro perforation process enables cigarette or tipping paper while cigarette making processes to reduce nicotine and condensate levels for non-filter and filter cigarettes as well. The OESP-1 devices opens fully new possibilities for cigarette or tipping paper ventilation during cigarette manufacturing by entire perforation cassettes integration into cigarette making machines as Max-S, Protos 80, Protos 90, Mark-9 etc.

Advantages during manufacturing

Compact all-over-dimensions, direct mechanical integration of perforation units, easy functional interfacing and full EMI acceptance in order of EN or NEC standards archiving high production efficiencies with controllable ventilation grades on highly automated cigarette making machines.

Liability and system investment

The ESP process OESP-1 has a high liability and is realizable with low investments and low running costs when compared with online macro or micro laser perforation processes. An online porosity control system OPSS-1 monitor continuously the air permeability, called optical online porovision or porosimeter, with a state-of-the-art technology to obtain a close-loop/feed-back to the perforation unit to keep ventilation grades constant.

Conclusion: Inline micro perforation process is possible to use for other mass products and application fields with full system integration in entire production lines as bag, sack, packaging manufacturing etc.

more details http://www.microperforation.com/online-perforation-cigarette.html

ON-LINE LASER PERFORATION with patent granted high speed multiplexer DE102004001327

A – laser source and IPM patent granted multiplexer with 8 optical channels

B – bobbin unwinder and perforation heads

C – tipping paper strips with 8 laser perforation lines

further information on request

Material treatment and microperforation in cluster systems

Web material as regenerated cellulose film, filter, cigarette, tipping, roll-your-own RYO, make-your own MYO, wall, decoration, transparent, coated, laminate, sack, bag or packaging paper, bonded fabrics, spun bonded non-woven, food, fruit, medical, under roof house or agriculture vegetable covering, packs, technical textiles, fabrics, laminate with base weights 20 g/m2-180 g/m2, thicknesses 10-80 microns, up to 20 g/m2 LPDE coatings are perforate electro statically micro, or by laser with micro or macro holes for wide range of application purposes.

Technology

ELECTROSTATIC NANO MICRO CLUSTER PERFORATION or material treatment, based at micro discharging and sparking, plasma tunnel effects with gas atomic ionization in nano second time windows. The pores are normally statistical irregularly distributed in controlled size ranges from 0.05-80 microns diameter and analogically, under LASER or MICRO or MACRO PERFORATION, arranged in diameter sizes from 60-200 microns, at best non-inclined holes und holes rows of diverse arrangement comprehension. For the naked human eye invisible electrostatic nano or micro perforations may be arranged in areas or zone bands with specific distances within its web. Controlled pore sizes in wide ranges from 0.050-80 micron diameters by holes sequences up to 16 million pores per second and 0.1-3 mill Joule discharge energy for each pore. Process and power electronics patent granted with DE10328937.

Performance

Arrangements of zones are usually carried out in width from 2 to 6mm and pores density of 15 up to 250 pores per square cm whereas the perforation of areas results in pore densities of up to 5 million pores per m2 in surface-all-over design. Electro static perforations allow porosity levels from 80-2,500 Coresta Units (ml/min/2cm2, 1,000Pa), equality from 40 down to 3 Gurley material web widths from 100-2,000mm at web speeds of up to 500 m/min, depending on porosity and material consistency in relation to its ability to perforate.

Physical Properties

One of the foremost postulation which can be applied to many application purposes and products containing bonded fabrics, bag or packaging papers, non-woven, etc. with gas or steam permeability but water in-permeability will be found at the application stage of the electrostatic nano micro cluster perforation. Which means pore sizes from 0.050-80 microns diameter by up to 5 million per square meter. This is due to the water’s greater surface tension which hampers the permeation through the relatively small nano or micro pores. These and other physical advantages of the relatively small pores necessarily demand the application of the cluster perforation method because alternative perforation or processes are NOT feasible, too expensive or simply uneconomical and would not lead to a successful application.

Products, applications, advantages

breathable and ventilated mass products as cigarette, tipping, filter, packaging, plug wrap, refinish or fine paper

booklet, bible, printing, flexo, magazine, promotion, flyers or newspaper with improved or modified surface property

decoration or gift paper with thin coating films

PVC laminate, Vinyl, decoration or wall paper to eliminate one side condensation effects

enable control gas exchanges, avoid rises of mildew or rottenness

join or corner Kraft paper tapes to avoid glue bubbles and enables material diffusion

fleece bonding material with thin plastic film layers for outdoor and under roof protection or covering, wooden houses, etc., enables gas exchanges

technical textiles for gas exchanges to avoid condensation processes

breathable overalls, heavy duty or disposable work dresses, trousers, aprons, jackets or shoes made of thin PE fleeces or other material

thin PP or PE contacted Kraft paper bag, cement sacks, plaster, maize, grain, pet food, granulate or powder for gained air outlet or blowing during filling processes with multiple time reduce efficiency

keep packed products in the same barrier condition as without micro perforation

extending storage, live time or durability of certain goods and products

biotopes and prevention of water pollution

leather or cloth inlets for comfortable non sweat wearing under wet, high humidity and tropical condition

soap, deodorant, hygiene, beauty creams, baby care or other packaging products which needs smell suggestion for marketing indication and buying advantages

vegetable, flowers or food with paper packaging replacements for gas exchanges

bread, rolls, fruits or food to improve the freshness and aroma

technical multi layer foils for industry, medical, bioengineering or filtration purposes, surface modification or improve roughness

micro filter, membranes, battery separation layers, bio or lab analytic, alcohol, liquid or blood filtration, clean room, agriculture plant applications

reduction or force growth rates of bio processes

more details http://www.micro-ventilation for mass-products

Differences and system integration

It is also used especially for additionally treating materials when aiming special characteristics by physical or regular process reasons what cannot be achieved by other process technologies. Moving material web base weights from 20-180 grams per square meters by thicknesses 10-80 microns are possible to use. Including defect inspection, process automation, moisture vapor transmission rate, abrasion resistance of lamination, water proof, ventilated or breathable fabrics. Our state-of-the-art industrially approved, sophisticated, compact, multi functional, optical online sensor scanning systems together or without electrostatic laser perforation technology operates precise and reliable 24/7, are integrate able into existing rewinding, slitting, spooling, spreading, printing, labeling, complex production lines or other machines and production processes as well. Also, they can be used as completely independent micro surface-all-over or zone perforation units. Fully new ranges of applications will be made available total new products with special features and properties.

High power laser multiplexer for industry applications as well for wide web micro perforation machines LPM-1 with tipping, packaging paper, non-woven, spun-bonded, textile, plastic films or other material substrates

Patent granted DE102004001327

Patent download http://www.microperforation.com/englishengineerreport.html

Introduction

A German-Thai-Chinese high-tech engineering company offers completely new possibilities with high power CO2 laser multiplexers for wide web applications as well for micro perforation with JUMBO-ROLLS with up to 200 individual laser perforations rows, automatic laser perforation head positioning, focus setting, web speeds up to 400 m/min, web widths up to 2,000mm and more. Several types of material web, e.g. paper, packaging, coated sheets, films, foils, metal sheets and other types of substrates can be micro perforate or treated. We are seeking for R&D, science or industrial partners in licence agreement, technical cooperation, new product or applications in USA and EU.

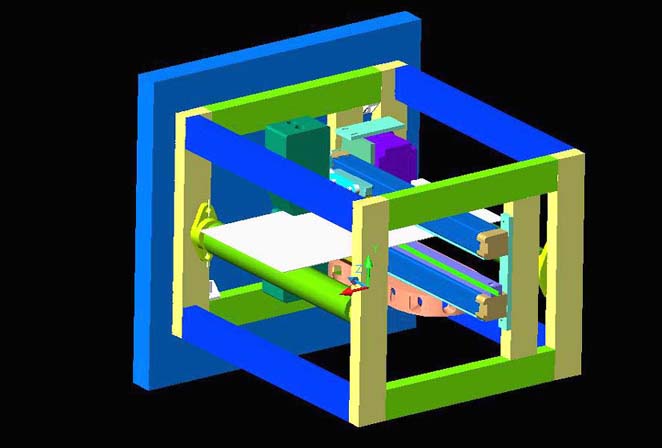

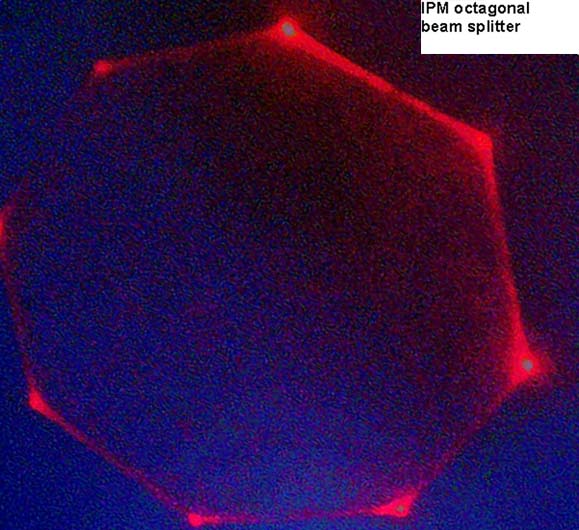

Working principle of high-power laser multiplexer

Through 2or 4 Kilowatt dual laser beam sources, two or four level high-power laser multiplexers designed for certain wave lengths from 500 nm up to 10.6 micron, new two level rotary cubic elements, or two quadruple beam splitters or polygons bent facets, using of new developed CO2 hollow waveguide fibres HWG HCW realizable up to 200 optical single channels with assembled focus heads direct on the production web material.

Without very extravagant, expensive of optical elements, alignments, lenses, divert mirrors, extended mechanical designs, etc.

Pulse sequences up to 4,000,000 per second, single shoots between 0.5 up 3.0 mJ, time windows from 1 µs up to 100 µs and e.g. holes sizes from 1 µm up to 100 µm or microns are possible.

Description for wide web micro laser perforation

Wide web laser perforation processes, equipment and machines permits e.g. tipping or packaging paper web width up to 2,000mm and more, up to 200 single laser rows across the web by holes sequences up to 4,000,000 per second. Depends of material consistence, perforability, holes sizes and densities web speeds up to 400 m/min, web widths up to 2,000mm, 25,000 meter roll-by-roll, automatic perforation head positioning and focus control, up to 20 bobbins in one cut which means up to 160 bobbins are now archive able without machine downtime. In addition the key element and integrated OPSS-1 porosity/position scanning system complete the feed-back and robot control system. The optical online multi sensor porosity/position control system OPSS-1 is located just behind the laser perforation section and rewind stand to control the perforated material web continuously and supply the data stream to the master PC and close loop.

Highly automated and motor adjustable focusing optics one each perforation heads are free position able across the material webs. That automatic procedure and their robot devices open now fully new ways in wide web laser perforations or other material treatments in high speeds ranges, large number of optical single channels and high pulses or holes sequences.

In addition with the optical online control systems OPSS-1 porosity, hole qualities and all hole row positions are continuously controlled and differences immediately compensate over master PC controlled feedbacks to the perforation system. Production rolls and products are finished without intermediate stops in high qualities and large quantities.

Other applications

The new high-power laser beam multiplexer open many other application fields, e.g. cutting, cut-offs, welding, surface finishing, drilling, polishing, forming, surface treatment, roughness improvement, etc.

Each of the 200 single perforation head can be positioned across the running web or static positioned material substrate. This automatic processes, equipments and devises open up completely new possibilities in industry, science or military or space laser applications.

more details http://www.microperforation.com/lpm-1.html

Anti piracy product design with laser cluster - ultra-high speed for Co2 laser beam control

Patent pending DE102004012081 download

Micro laser perforation

Laser perforation in general, possible to perforate by pulsed or enlarged and focused laser beams are holes sizes from 60 to 200 micron at holes densities of typical 10 to 30 holes per cm, holes sequences from 100,000 to 400,000 holes per second at maximal 16 punctured laser rows, register distribute cross material web width with traditional systems or machines. Means for cigarette, tipping, plug wrap, filter, packaging, pack, tear tape, plastic and other material. With porosity levels from 100 up to 3,000 C. U., normally in web widths from 100 to 500mm at web speeds of up to 600 m/min, depending on porosity and material consistency in relation to its ability to perforate.

IPM’s laser cluster material treatment, perforation technology

IPM’s laser cluster material treatment perforation technology LPM-1 is patent grantededed by DE102004001327 operates with quadruple Co2 or other laser types, beam inputs up to 4 Kilowatt to supply a high power twin level, vacuum operates multiplexer. High spins of quad laser beams generates up to 200 individual optical output channels to supply special made flexible hollow fibers HCW, HWG, fibre optics, to archive micro perforation rows cross moving web or static material, combines automatic positioned laser perforation heads, each with motor driven focus, web speeds up to 400 m/min, web widths up to 2,000mm, up to 2,500,000 holes per second, jumbo roll-by-roll production, optical in-line permeability scanner control for perforation line position and quality, porosity feedback, hi-tech automation level and other features. Each laser micro perforation lines can archive 100 up to 1,000 C.U.

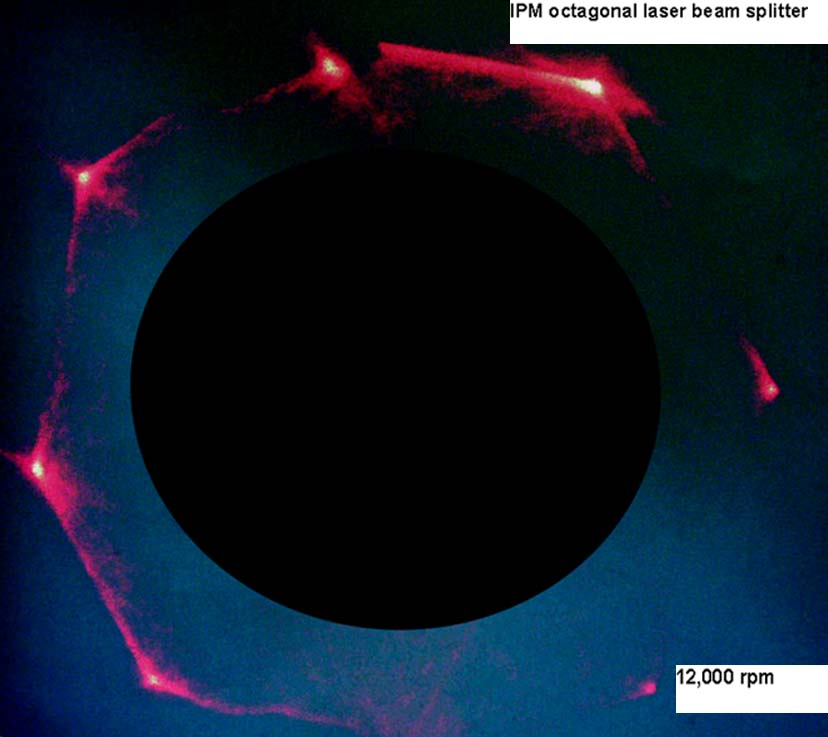

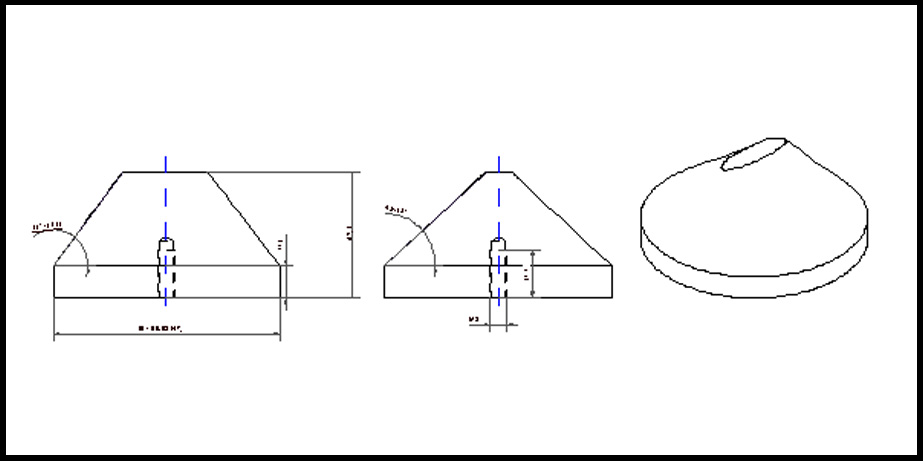

Super high speed for Co2 laser beam control

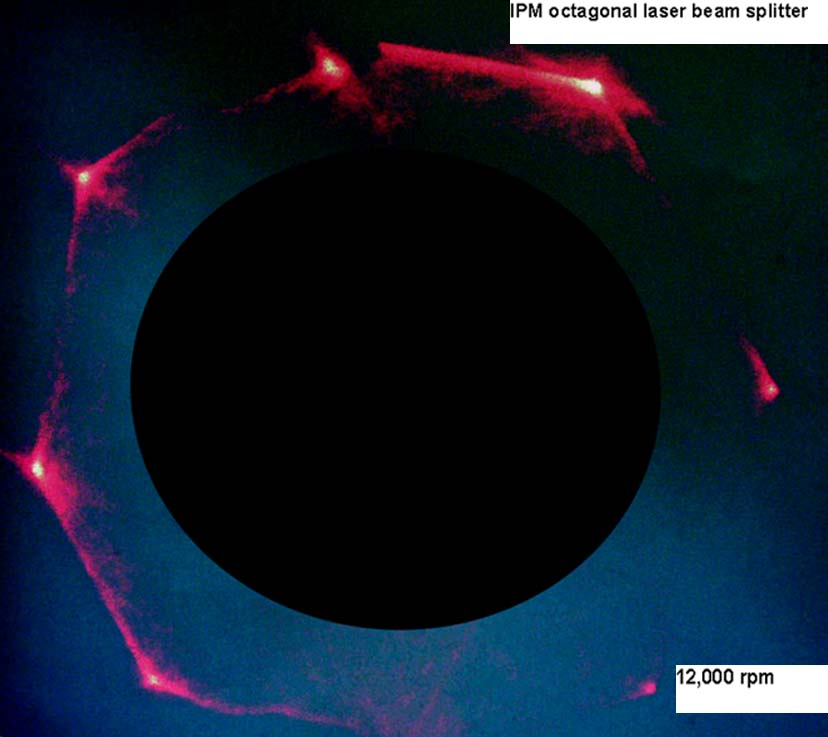

Technologically performed of Piezo oscillators or ultra-high scan speeds up to 4,000 Hz or 240,000 rpm with commercial air-bearing motors.

REAL galvanometer scanner alternatives, precise laser beam deflection up to 4 Kilowatt Co2 by high dynamic performances.

From 8 up to 15mm laser beam aperture diameter, advantage beam quality factor M2 less then 0.9 for focus spots down to 60 micron.

Absolute diffraction limits, because small focused spot sizes which are proportional inversely of laser beam input diameter.

In other words, larger laser beam apertures will produce smaller focused spot sizes, as especially needed for micro cluster perforation, drilling and other micro machining applications.

Spin actuator with special optical coating, optimized outer shape, very precise rotation balance by inner body laser ablation, hollow body with inner cavities by low mass material condition, excellent relation of stiffness-to-weight, high hardness, adapted total vibration free vacuum cylinder case, asymmetrically rotary reflection cones from 40 up to 80mm base diameter, average mirror surface roughness lower as 0.1 micron, form accuracy lower 0.01 micron, operation sequences are precise synchronize with material speed.

Envelope curves of the selected perforation pattern are storage and calculated by PLC control before single holes and holes groups supervised during production processes.

Product process advantages enable total different product indicators and milestones against other laser perforation or material treatment processes which allows significant product property, trademark indications, patent claims, unique company features in micro perforation of tipping, cigarette packaging or other paper or material.

E.g. wide range of laser perforation groups as common active ventilation zone to obtain several advances in air stream distributions into cigarette filter, perfect perforation line guiding around cigarette filters or other food, domestic, industry products to assure constant porosity results.

Several pattern or wave line design for different brands, number of holes or pattern with 10 or 20 per cm length are constant, porosity range from 100 up to 1,000 C.U., holes sizes from 60 up to 120 micron, holes densities from 100,000 up to 500,000 holes per second in total.

From 1 up 6 perforation pattern, lines, marks or scripts can combines a group, perforation hole, pattern quality or porosity remains in standard levels.

Other web material, substrate or products are treatable in similar processes, existent laser perforation, treatment machines are able to modify with new optical, micro mechanical and control elements.

Low investment and finance budget of technical modifications because exchanges of certain elements, complete devices are adaptable on existent off-line perforation machines or other laser treatment handling systems.

Capability to adapt beam divert devices or units at on-line perforation system at cigarette making machines up 12,000cpm.

Outstanding product applications

For web or sheet material, metal, isolation, foil, film, plastic, substrate, leather, textile and paper enables now large number of possibilities for micro hole position, different pattern, design, wave, zigzag, cryptograms, scripts, marking, scribing, scratching, tear off lines or others which generates. E.g. optimize air distribution characteristics into cigarette filters, unique anti counterfeit piracy indication and not countable product advantages.

Special remark creates fundamentally new product properties, e.g. as final products for mouthpieces with tipping paper at cigarettes or other tobacco, packaging, security products, flip off or hinge-lid packs.

Specific indication of brand names to recognizable for everyone and even for product buyers, if micro design, holes, patterns, holograms are to see with magnified views only.

Or sensitive touch able as Braille scripts generated by micro cluster cryptograms or holograms.

MLL-1 targets many existent and new applications with high speed scans of laser beam divert in horizontal or vertical position.

Sophisticated ultra high speed spins optical divert elements allows low budget modifications at existent systems and production machines.

Micro-Laser-Line technology means real alternative for high speed galvanometer scanner to archive micro cluster perforation, pattern design, waves, zigzag, packages line, cryptogram, company logo, hologram, anti counterfeit piracy contours for security paper, safety, bank notes, cards, metal sticker, printing, laminating, coating, fruit, food, bread, vegetable, agriculture covering, transparent films, plastic sheets, holographic paper, cigarette, tipping, filter, aluminum foil, shrinkable film, tear tapes, label, cardboard, matrix, marking, scribing, automotive, pharmacy, smoking, chemical or medical products, electronics part, chips, indicators, writing contours or profiles, embossing or holographic. The patent of devise, process and product properties are pending as DE102004012081.

Other industry fields

The conception of high power twin level laser beam multiplexer enables plenty options in other industry application fields as cutting, cut-off, welding, surface finishing, drilling, ablation, cleaning, micromachining, polishing, forming, melting, surface treatment, roughness improvement. Each of 200 single laser beam and coupled flexible hollow fiber HWG HCW up to 3,000mm length allows treatment processes or perforation heads for precise, compact, robotic positioning in X/Y direction of running web or static placed sheet material.

Automatic PLC controlled processes, equipments and devices enables now outstanding possibilities in industry, metal, plastic, domestic, tobacco product, medical, hygienic, wall covering, security cards, bank notes or food application.

LPM-1 means cluster material treatment at wide web, large area, surface or whole material treatment, high power twin or quad rotation laser beam splitter, mirror into a vacuum twin level multiplexer, Co2, YAG, Fiber, Excimer, UV laser with multiple optical inputs, flexible hollow fibers, HCW, HWG up to 200 output channels. Material treatment and robotic handling for stainless steel, ceramic, aluminum, wafer, glass, ceramic, brass, copper, wafer, silicon, plastic sheets, titanium, jewelry, silicon, solar, panel, photovoltaic, micromachining, slitting, rewinding, refining, hybrid laser cutting machines or stand along systems.

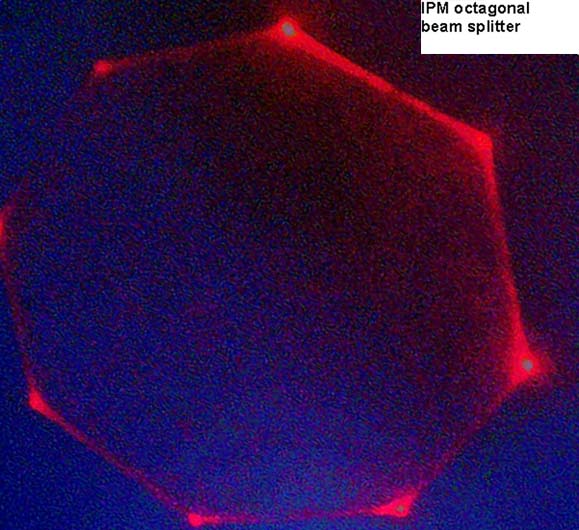

High-speed rotate octagonal beam splitter

more details http://www.microperforation.com/mll-1-laser-perforation.html

Renewable energy switching converter

Patent granted DE10328937 download

A new twin mega power medium frequency switching converter for renewable energy works with hybrid drives, compact EMI safe semiconductor power electronic stages to convert solar or wind renewable energy for direct supply into the 50 or 60 Hz main net. High-tech engineering company IPM develops and patent granted DE10328937 such and other application.

Advantages are based on uses of standard switching units with extended IGBT, MOSFET, HVFET semiconductor modules as twin cluster frequency shifting for applications as medium frequency corona substrate treatment, micro cluster electro static perforation, ac/ac, ac/dc converter, drive units, fuel cells operation, upward or downward converter, laser diode stack power supply equipments, plasma jet, heavy ion research, train, vessel, boot, mining power electronics. Frequency up to 200 KHz and power level up to 200 KW is possible.

More information on our websites.

IPM is looking for science, industrial, power electronics, marina, mining or others partners who are interest in licence agreement, technical cooperation for other wide application fields.

Introduction

On a high level operate engineering company develops a dual, high power, high frequency switching unit which works with hybrid drives, compact EMI safe semiconductor stages, supporting capacitors, high voltage ferrite transformers to generate HV short pulses and sparking groups. Advantages are based on uses of standard circuits with extended semiconductors for e.g. nano, sub or micro perforation applications, corona treatments etc. The company is looking for science or industrial partners who are interested in a licence agreement and / or technical co-operation.

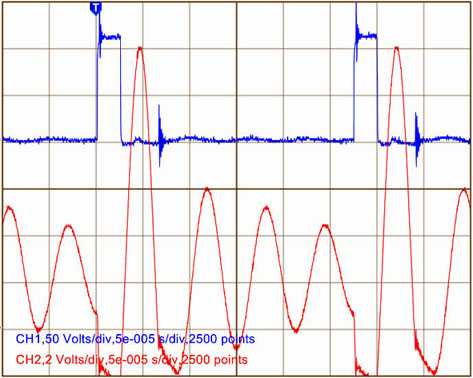

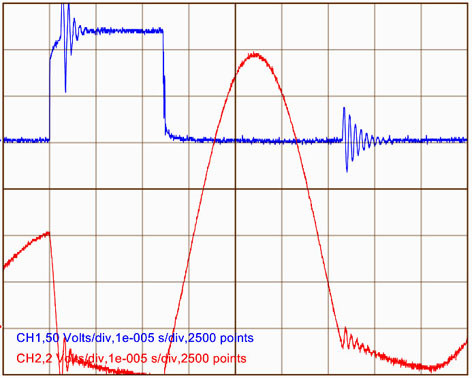

Working principle

Industry application of electrostatic perforation for fast running paper webs using IGBT, MOSFET or HVFET semiconductor power stages. These circuits working as upward converters with power pulses in ranges from 5 µS up to 25 µS and high current peaks up to 300 Amps on a serial connected inductivity and loading capacity that the secondary ferrite transformer coils supply sparking electrodes up to 50 Kilovolt.

The circuit works itself with alternating clock frequencies and changes of pulse widths a common load condenser and coupled primary inductance of a ferrite high voltage transformer as upward power/pulse converter and non resonance frequency operation.

A safety circuit logic and two hybrid drivers allows a alternately switching of semiconductor A and B which generating higher operation frequencies and power levels meanwhile the electrical and thermal conditions remains on each in the same range as a single switching unit.

Circuit advantages

A controlled pulse timing into a certain time window with a constant or variable frequency generating hole sizes and hole sequences with high voltage sparking through the material webs by nano or micro perforation. The repeating frequencies of the entire circuit can up to the double switching frequency as of each semiconductor stage.

A changeable current in the spark channel are feasible with total switching frequencies up to 150 kHz. And in the same time the dual semiconductor switching unit allows a double power level as just only with one switching element is possible.

Dual IGBT, HVFET or MOSFET semiconductors in high power, high current, high voltage circuits obtain in electrostatic nano, sub micro perforation, corona treatment or other switching application frequencies up to 250 KHz, power level up to 30 KW and more. Higher power efficiencies and harder switching periods are further advantages.

In conclusion the approximately double frequency and power level operation obtains higher switching efficiencies, much more perforation power or higher corona treatment levels which are depend of the industry application.

Nano, Sub Micro Perforation

Perforation results are now achieve for nano, sub and micro perforation of flexible webs with ultra small pores and products made of these materials. Materials finishing are of interest for numerous demands in the field of packaging, in filling, non-woven industry, technical and science applications, etc. For many years fine and other paper webs with base weights between 20 up to 150 g/sqm have been perforated electro statically in large surface all over areas or zone designs of 2.0 up to 6.0mm width.

Pore sizes from 0.05 up to 60 microns or 1 to 100 microns, pore distributions of up to 4 Million per sqm in area perforation or respectively 3OO holes per sqcm by zone perforation and hole sequences up to 16 Million per Second can be reached. Air permeability or porosity ranges are among from 50 up to 2,500 C.U. (ml/sqcm/min) respectively 3 to 50 l/sqm/sec. (Franksystem) by paper web speeds up to 450 m/min and web widths up to 1,200 mm are archive able.

Electrostatic perforation processes and machines, corona treatment, surface treatment, high power switching devices, power supplies, AC&DC and other switching converter systems, drives, etc. Fine paper, cigarette, packaging or other fine paper industries, corona system manufacture, switching device manufacture, high-power converter equipment, AC/DC, DC/AC industry etc.

The new dual semiconductor circuit design allows applications to build hybrid drives, semiconductor high-level stage, upward, downward or other converters or generators which operating with supporting capacitors, high-voltage ferrite transformers in an extremely compact and modular design. Several advantages are the high efficiency of pulse/power transmission and energy ratios.

Traditional corona or other type of medium generators up to 30 KHz operation ranges are easy to modify to a double frequency and power levels operation.

more details http://www.microperforation.com/igbt-esp-unit.html

Optical OPSS-1 porosity permeability scanning systems for substrates

Patent pending DE10251610 – China patent granted 200310104764

Sophisticated, multi functional, optical sensor scanning systems

IPM has developed a number of new, patent pending, stationary, scanning optical control processes, devices and systems for fast moving webs or fabrics to detect very precise and reproduce their specified product properties in online operation during production.

Introduction

OPSS-1 OPRL-1 vision control systems are equipped with multiple IR, NIR, VIS monolithic spectral color sensors, precision line lasers, CCD imagine devices, DSP, ATMEL and INFINEON sensor internal controllers, own firmware, high speed data link, at scanning speeds from 20 up to 500mm per second, at web widths up to 5000 mm, measuring gaps from 2.0 up to 5.0 mm, optical inline detection of permeability, porosity, spectral transmission, opacity, extinction, particle absorption, porosities ranges from 80 up to 5,000 C.U. (Coresta), respective from 50 down to 3 Gurley, position control of micro perforation lines with 0.1 mm accuracy, nano micro pores from 50 nm up to 200 micron diameter by up to 300 pores per cm2. With real time data determining of certain parameters, optical transmission, spectral grades, porosity integrals, envelope curves, internal calculated measuring values.

Thus direct with close loops and feedbacks to the power electronics of fabrics treatment units. Micro perforation or other system makes it possible to compensate any changes in web treatment parameters and their partial locations so that each jumbo roll as well single, quad bobbin sets can be produced quantity and quality controlled without intermediate stops in order of ISO 9001/9002 certifications.

Thus sophisticate, precise, liable, repeat accuracy, easy visualized, optical online measurement techniques archives perfect ways to control and convert pneumatic, fluid, gas, jet streams, static permeability, naturally porous grades, filtration levels, breathable or ventilation effects, etc. at fast moving webs. Their conditions can be easily met by using optical transmission technology thanks to described processing in fully online stationary or scanning control units, extremely small pore dimensions, high fabric speeds up to 1,000 m/min by high repetition rates. That completely independent from base material properties as consistency, coloring, density, formation, pin holes, smoothness, stretching, shrinking, brightness, opacity, optical spectral property, gauging thickness weight, moisture content and other known influences.

Applications

The electrostatic nano or micro perforation, including Co2 slab fiber yag excimer diode laser, other material going trough or surface treatment, as well for micromachining and nanotechnology, is usually used depending on quality at fine, rotogravure or offset printing, holographic or publishing paper, writing, magazine, newspaper, packaging, bonded fabrics, non-woven, filter, coffee, tea, bag, sack, craft, food, fresh fruit, force, reinforce, tipping, cigarette, plug wrap, fiber, facial tissues, toilet, decoration, wallpaper, gift, watermark, towels, bleached dyes shiny or clay, recycling, booklet, bible or other special paper, certain plastic films, foils, coating, laminating, extruding, Polyofine, Polysulfone, Elastomer, textile, Polymer or most of that varied types.

It is also used especially for additionally treating materials when aiming special characteristics by physical or regular process reasons cannot be achieved by other process technologies. Material base weights from 10 up 150 grams per m2 by thickness from 5 up to 100 micron are possible to use. Including defect inspection, process automation, moisture vapor transmission rate, abrasion resistance for lamination of waterproof and breathable fabrics.

Our state-of-the-art, industrially approved, sophisticated, compact, multi functional, optical online sensor scanning systems together or without electrostatic, laser perforation technology operates precise and reliable 24/7, are integrate able into existing rewinding, slitting, spooling, spreading, printing, labeling, complex production lines or other machines and other production processes as well. Also, they can be used as completely independent micro surface-all-over or zone perforation units. Fully new ranges of applications will be made available total new products with special features.

Specific information by website links and patent resources.

Introduction

A German-Thai high-tech, engineering company has developed an optical online porosity or permeability scanning system. It works with two different multiple sensors units, i.e. precise line laser, colour sensors and internal controller unit for real-time positioning and porosity control in light transmission mode whilst scanning across the fast running webs up to 600 m/min. The main advantage compared to existing technologies is the measurement of perforation zone/line positions and porosity levels in the same time while the scanner system across the running material web up to 2,000 mm width.Science, R&D, Universities, industrial partners for a licence agreement and / or technical co-operation are sought.

Working principle

The porosity control of natural porous and/or perforated web material in laser or electrostatic perforation systems which are produced in speed ranges up to 600 m/min and web widths up to 2,000 mm is difficult to measure with pneumatic systems because of following disadvantages: web tangency, web toughing, material flaking, formation of folds, dust and dirt entering the system.

These difficulties can be overcome with stationary or scan, optical porosity measurement systems for porosity ranges from 80 up to 5,000 Coresta units (ml/2cm2/min) respectively 3 to 50 l/m2/Sec. (Franksystem) by nano, micro or macro holes sizes from 0.5 up to 500 microns and hole densities from 10 macro holes per cm up to 400 holes per cm2.

The optical online porosity control technology is designed to scan perforation zones with a multiple sensor and their positions with a precision line laser to determine all data in real time with an internal controller unit. It controls roll material or bobbin formats, either as a stand-alone unit or mechanically coupled with existing scanning units which measure the material weight, thickness, opacity, density, brightness, smoothness, formation, etc.

By laser and electrostatic perforation in bobbins and wide paper web formats optical online control processes and their devices are indicated with transverse movements across the web and simultaneously collections of perforation positions and porosities by two different sensor systems.

Both measuring systems move transversely between 50 up 400 mm/Second over the fully web width. They consist of a line laser detect the quality and position of single holes, groups of holes or defined perforation zones into the measuring gap of 5.0mm. At the same time, the multiple light transmission sensors monitor all porosity profiles and determines envelope curve and calculate the integrals.

Advantages

Thus direct feedback into the perforation system makes it possible to compensate any changes in terms of porosity and perforation locations so that each jumbo production roll up to 25,000 meters as well single or quadruple bobbin sets can be produced and controlled without intermediate stops and certificated in quantity und quality on their end.

Natural porous or perforated web material as cigarette, tipping, plug-wrap, filter, packaging, non-woven, flees, coated paper as well micro or macro perforated plastic films as BOPP, LDPE, PP, EVA, HDPE, etc. are controllable with the OPSS-1 scanning system.

OPSS-1 optical porosity vision control - download OPSS-1

more details http://www.microperforation.com/opss-1-optical-online-porosity.html

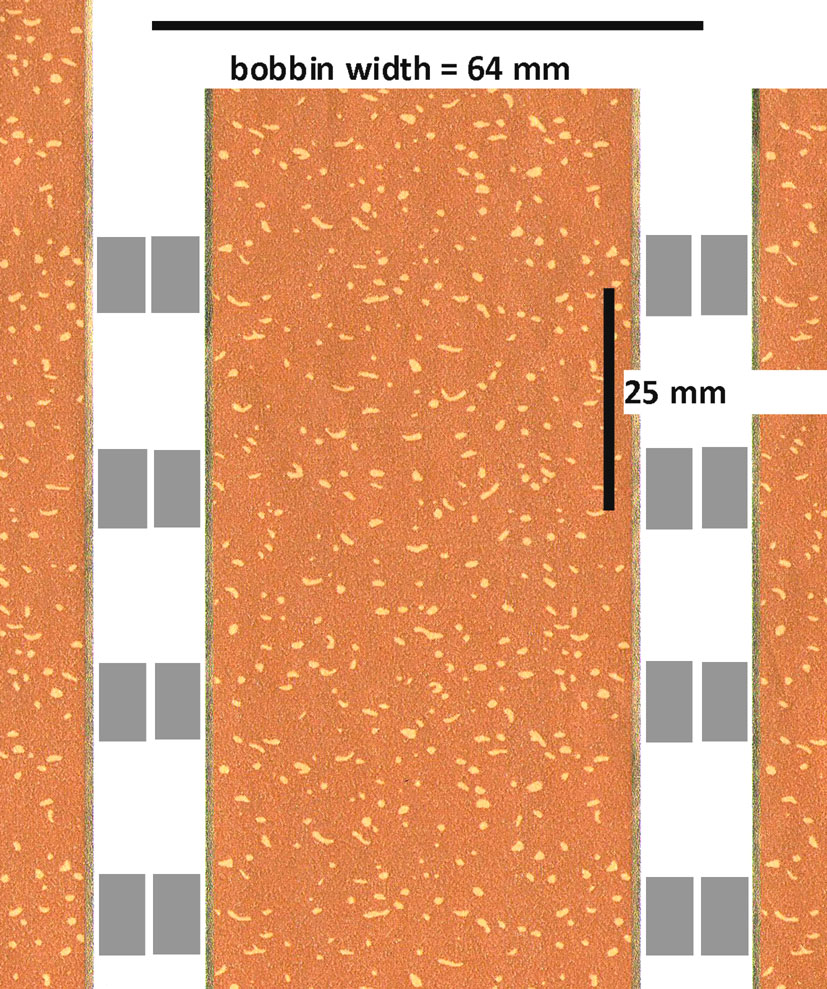

OPSS-1-B print inspection with hi-speed camera scanner for QUAD bobbins at laser perforators - download OPSS-1-B

Print inspection –

tipping paper – quad bobbins

Patent applied in Germany and P.R. of China

Conditions

Results

maximal capture rate : cap =

speed/Y-field = 8.000mm/sec/25mm = 325

capture/sec.

inspect with step 1 bobbin A : (Δt0

--- t1)*cap =

0.32s*325capt/sec. = 104 captures while web running

inspect with step 2 bobbin C : (Δt3

--- t2)*cap =

0.32s*325capt/sec. = 104 captures while web running

inspect with step 3 bobbin D : (Δt3

--- t4)*cap =

0.32s*325capt/sec. = 104 captures while web running

inspect with step 4 bobbin B : (Δt1

--- t2)*cap =

0.32s*325capt/sec. = 104 captures while web running

(Δt0 --- t1) = (Δt1 --- t2)

= (Δt2 --- t3) = (Δt3 ---

t4)

full scan OPSS-1-B : 2*(∑t1, t2, t3, t4) =

1280*2= 2560ms = 2.56 sec.

by (2.56 sec.*8 m/sec) 20.5

meters printed tipping paper by full scan

∑ captures :

(step1+step2+step3+step4) = 4*104

captures = 404 captures

Continuous inspect length

by bobbin A, B, C, D: speed*inspecting =

8.000mm/sec*0.32sec = 2.6

meter

Continuous inspect printing

length of each bobbin strip : 2.6 meters with 104 captures

each of 25 mm single

printed fields by 8 m/sec. speed

In-situ dyne and surface tension control at running plastic films or other substrates patent download: http://www.microperforation.com/englishengineerreport.html previous patent application DE19543289 - down load ODSTM-1-PATENT

Dynes control

Described is a method and device for optical inline tough less

surface tension control ODSTM-1 by which the fast moving substrate runs

through the measuring gap. It’s transmitted with a chromatic

beam and spectral selected light source were two optical channels are

displaced and polarized by 90 degree to each other. Both optical axles

are precise and motor driven shift able in certain angles from 25 up to

65 degree. The spectral light photons, transmission, extinction,

absorption grades are detectable by two optical CCD imagine vision

devices which are integrate in the sensor case on the other side of the

substrate.

Material

Moving substrates means plastic foils, flexible, high-tech films, laminate, coating, bonding, labeling, co-extrusion, BOPP, LDPE, LLDPE, HDPE, MDPE, MAS, MEV, PET, FEP, PP, PE, PS, PO, EVA, PTFE, PVC, PTFE, DPC, BOPS, Vinyl, Polyester, Wrapping, Olefin, self-adhesive tape, high strength, cross-laminated, adhesive-coated films, reflective or magnetic sheeting, automotive tape products, inkjet media, Polyethylenex, heat sealing, sewing of plastic film, pressure sensitive tapes for the entertainment industry, graphic and specialty arts for general industrial and electrical applications, building or engineering industry, photographs, masking or printable plastic films, flat or corrugated rigid foamed thermoplastic sheets, polycarbonate, acrylic, PETG.

Extruded or polished cellulose, optical grade polycarbonate, sheets for IR or laser protection, welding filter grade sheets, films for video, imaging, capacitor or thermo transfer applications, foamed polypropylene film with decorative ribbons, binary-oriented polystyrene sheets, multi layer co-extruded film, high impact PVC and PETG, polyimide film, tape and flat films for aerospace automotive medical agriculture marine automotive household commercial domestic construction industry, municipal and leisure applications, clear matt semi matt finishes or colored, micro porous membranes for use in alkaline lithium batteries, fuel cells and filtration equipment. By gauges from 10 to 100 micron, fabric widths up to 10,000mm and web speeds up to 18 meters per second.

Optical properties

Material specific wavelength selection between 1,200 up to 1,800nm, material specific finger prints, molecular spectral properties, transmission grades, optical angle scanning, Lambert Beersche law determining, ultra low level stray scatter light detection, polarization, slot diaphragms, transverse displacements control the light beams along/far from the optical X and Y axes. The results are extreme scattering, diffraction, NIR, IR, stray light photons generation into the layer areas at both sides of the moving substrate.

Their reflected and transmitted light intensities enables the determination by defined formulas and data matrixes the surface tension values in ranges from 28 up to 62 mN/m which are direct associate and bond to real static values for Statistical Quality Control (SQC).

And this entirely independent of the material specific influences as like surface consistency, thickness, density, weight, opacity, coherence, filling, stretching, shrinkage, structure, co-extrusion, polar grouping, temperature, intrinsic motivation or viscosity, hydrophobia, hydrophilic molecules, hydrogen, photonics, mol mass, moisture, water steam proof, bi-layer, polymer, patterning, nanostructure, irradiation, isotopic, catalyst, multi atomic, coherence, absorption, photo mask effect, roentgen, X-ray, radiation, resonance bands, REM, TEM, FIC, IEC, ESCA electron spectroscopy for chemical analysis ASTM or ATR method, property, ellipsometry, opto-acoustic photonic liquid effects, pre material treatment as corona, plasma, flam treatment.

Specific information by website links and patent resources.

The former patent application DE19542289 A1 concerns a method and device for optical dynamic, i.e. a non-contact, in-line surface-tension / surface-energy measurement for running substrates whereby the detection can be in the transverse-direction or in the running-direction of the web.

In the context of this invention,

running substrates or moved web

material is to be especially understood as being plastic films like PE,

PP, LLDPE, HDPE, BOPP, LLDPE, EVOH, PTFE, FEP, MOV, PET, PS, PMMA,

PBMA, PVC, PA and also laminated or coated film or paper webs which

still show a measurable optical transmission in the wavelength range of

1,200 up to 2,200 nm.